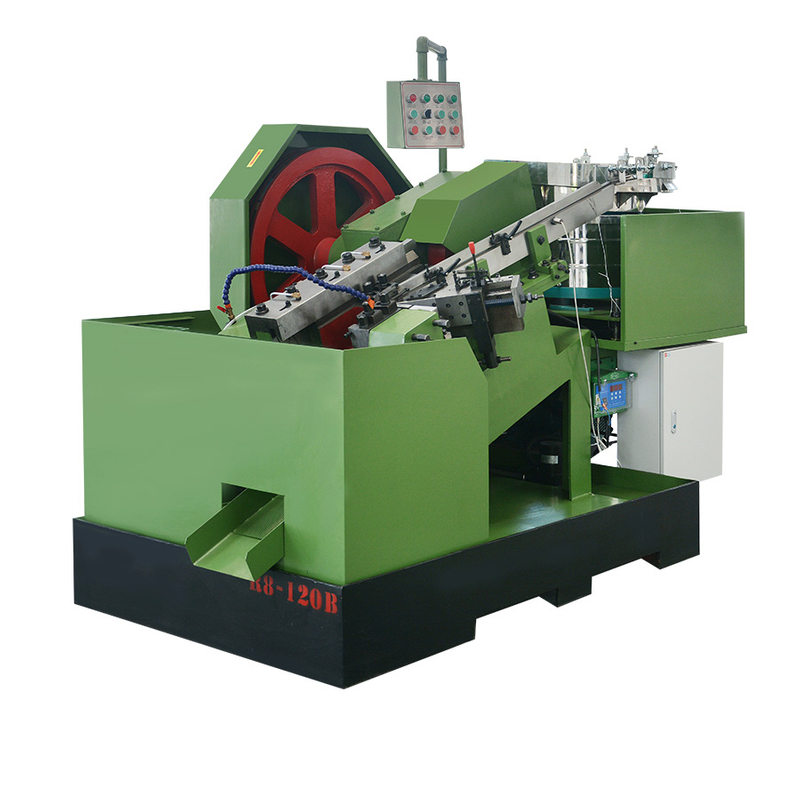

Thread Rolling Machine

The Thread Rolling Machine are specialized industrial machines used to create external screw threads on cylindrical workpieces by rolling or pressing rather than cutting. This process is known as thread rolling and is a form of cold working, meaning it is performed at room temperature without the need for heat.

Thread rolling machines create threads by using one or more dies (also known as rolls) that press against the surface of the workpiece. As the dies rotate and move along the length of the workpiece, they displace and flow the material into the desired thread shape. This process results in a stronger and smoother thread than those produced by cutting processes because the material is compacted rather than removed.

Thread rolling machines are commonly used in the production of screws, bolts, studs, and other threaded fasteners. They are widely used in industries such as automotive, aerospace, construction, and general manufacturing.

Overall, thread rolling machines provide a reliable and efficient way to produce high-quality threads on a variety of materials and are essential tools in many manufacturing settings.