Customer Review: Full Cover Thread Rolling Machine

Date: August 14, 2022

Reviewer: John Doe, Manufacturing Manager, DOC Fastener Co.

Product: Full Cover Thread Rolling Machine

Rating: ⭐⭐⭐⭐⭐ (5 out of 5 stars)

Review Title: Exceptional Performance and Precision

Review:

I've been in the fastener manufacturing business for over 20 years, and I can confidently say that the Full Cover Thread Rolling Machine we recently purchased has exceeded our expectations in every way. Our company specializes in producing high-quality threaded fasteners for the automotive and construction industries, and this machine has become a cornerstone of our production line.

From the moment we installed the machine, we noticed a significant improvement in the consistency and quality of our threaded products. The full cover capability ensures that the threads are uniformly rolled over the entire length of the shank, which is crucial for maintaining the integrity of the fasteners.

One of the standout features of this machine is its durability. We've been running it at high production rates, and it has shown no signs of wear or decrease in performance. The machine's robust build and reliable design have been instrumental in keeping our operations running smoothly.

The precision of the threading is exceptional. The threads are clean and sharp, and there's minimal burring or damage to the material. This has helped us reduce waste and improve our overall yield, which is a significant cost-saving factor.

Another aspect that stands out is the ease of operation. The machine's controls are straightforward, and the setup time is minimal. Our operators were able to get up to speed quickly, and the machine requires minimal supervision once it's running. This has allowed us to maximize our production efficiency.

Customer support has also been excellent. Any questions or concerns we had were addressed promptly and professionally. It's clear that the ARIDA stands behind their product and values their customers.

In summary, the Full Cover Thread Rolling Machine has proven to be an invaluable asset to our business. Its combination of precision, durability, and ease of use has significantly impacted our bottom line. If you're in the market for a reliable and efficient thread rolling machine, I highly recommend considering this model.

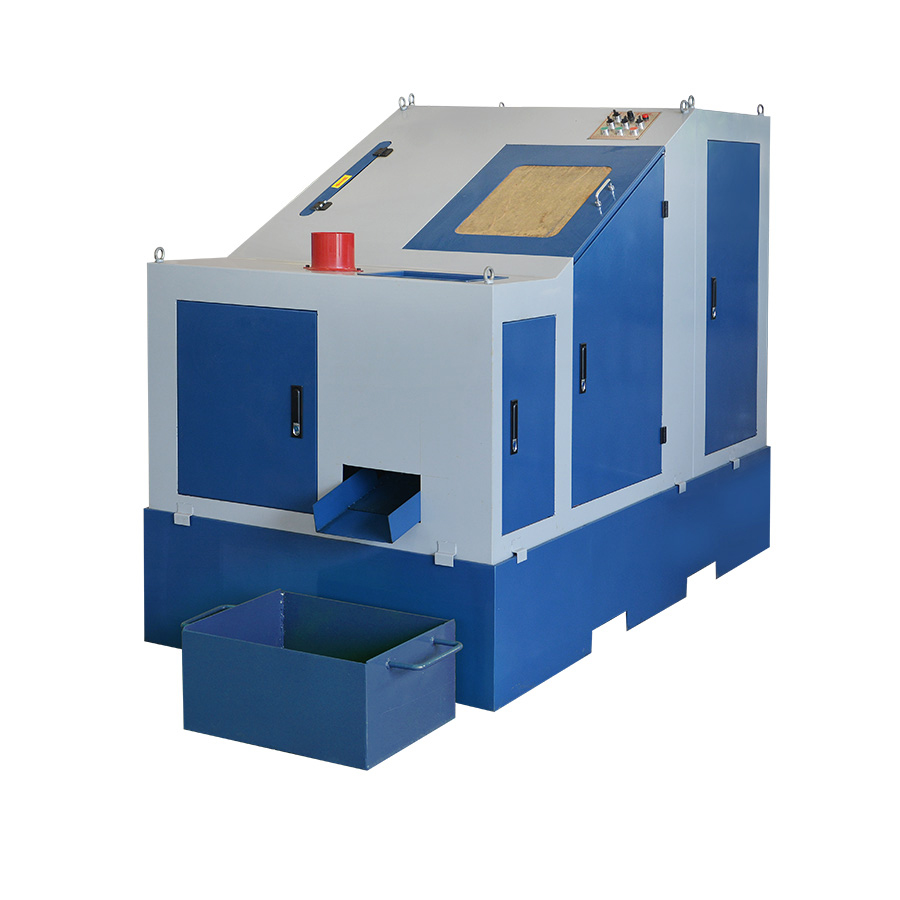

Full Cover Thread Rolling Machine

Full Cover Thread Rolling Machine