1. What is a Nut Forming Machine?

A nut forming machine is a specialized piece of equipment used in manufacturing to shape and form nuts from metal blanks. It typically includes a powerful hydraulic or pneumatic press, dies, and punches that deform the metal into the desired shape.

2. How Does a Nut Forming Machine Work?

The machine operates by positioning a metal blank in a die set, then applying force through a punch to deform the blank into the shape of the die cavity. The process may involve multiple stages, such as swaging for hexagonal shapes and thread rolling for creating threads.

3. What Types of Materials Can Be Used in Nut Forming?

Common materials include steel, stainless steel, brass, bronze, and aluminum. The choice depends on the application requirements, such as strength, corrosion resistance, and conductivity.

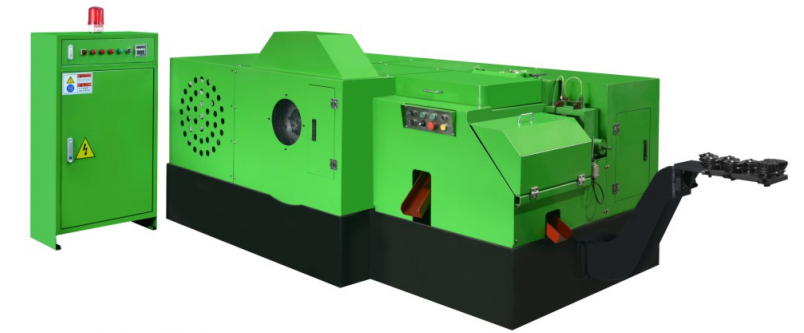

4. What Are the Main Components of a Nut Forming Machine?

The main components include the machine frame, power source (hydraulic or pneumatic), die set (punches and dies), feed mechanism, and control system.

5. Can Nut Forming Machines Be Automated?

Yes, many nut forming machines can be automated with the help of robotic feeders, sensors, and computer-controlled systems. Automation increases efficiency and reduces the need for manual labor.

6. What Are the Advantages of Using a Nut Forming Machine?

High Production Rates: Capable of producing large quantities of nuts rapidly.

Consistency: Ensures uniformity in the nuts produced.

Cost-Effective: Economical for mass production once set up.

Flexibility: Can be configured to produce different types and sizes of nuts with minimal changeover.

7. What Are the Disadvantages of Nut Forming Machines?

High Initial Investment: The machinery can be expensive to purchase and install.

Specialized Knowledge: Requires trained personnel for setup, operation, and maintenance.

Limited Flexibility: Changing the product line may require significant setup time and resources.

8. How Important Is Tooling in Nut Forming?

Very important. The dies and punches must be precisely manufactured and maintained to ensure the quality and accuracy of the nuts produced. High-strength materials are used for tooling to withstand the repeated stress of forming operations.

9. How Do You Maintain a Nut Forming Machine?

Regular maintenance includes:

Cleaning and lubricating moving parts.

Checking and replacing worn tooling.

Inspecting electrical and hydraulic systems.

Performing scheduled servicing as recommended by the manufacturer.

10. Can Nut Forming Machines Handle Custom Designs?

Yes, with the appropriate tooling and programming, nut forming machines can handle custom designs. However, this may require specialized tooling and potentially longer setup times.

11. What Safety Precautions Should Be Taken When Operating a Nut Forming Machine?

Safety precautions include:

Ensuring all guards are in place.

Providing proper training to operators.

Using personal protective equipment (PPE) such as gloves, safety glasses, and hearing protection.

Following all manufacturer guidelines and local safety regulations.

12. How Do You Troubleshoot Common Issues in Nut Forming Machines?

Common issues include:

Misalignment: Realign the dies and punches.

Worn Tooling: Replace worn or damaged dies and punches.

Irregular Threads: Adjust thread rolling parameters or replace the thread rolling dies.

Jamming: Clear any blockages and inspect for bent or broken components.

13. What Is the Expected Lifespan of a Nut Forming Machine?

With proper maintenance and care, a well-built nut forming machine can last for many years, often decades. The lifespan can be extended through regular maintenance and timely repairs.