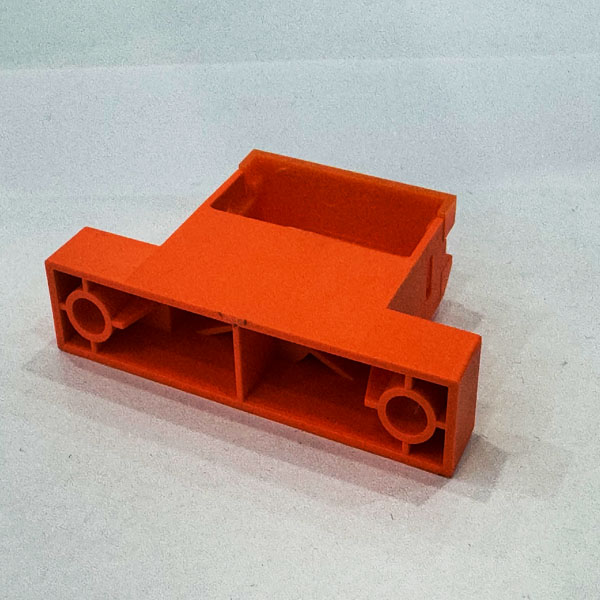

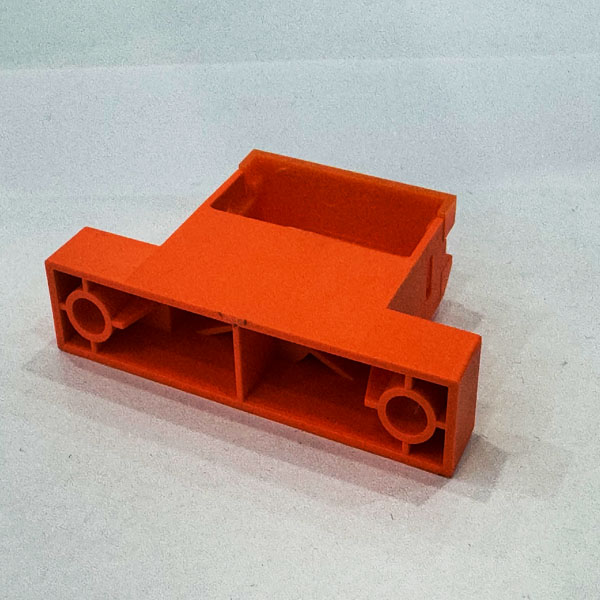

The Precision Engineered High Voltage Extraction Support for New Energy Batteries is a specialized component designed to provide structural support and facilitate the safe and efficient extraction of high-voltage batteries in various applications, such as electric vehicles, renewable energy storage systems, and industrial equipment. This product is meticulously engineered using advanced injection molding techniques and high-quality materials, such as lightweight bronze, to ensure durability, reliability, and optimal fit.