Arida New Energy's Power Battery High Voltage Extraction Support is a cutting-edge solution designed to enhance the performance and safety of high-voltage applications in the realm of energy storage, particularly for lithium-ion batteries used in electric vehicles (EVs) and stationary energy storage systems. This product focuses on addressing critical challenges associated with high-voltage technology, such as ensuring stability and preventing degradation of the battery system under demanding conditions.

The Power Battery High Voltage Extraction Support includes advanced electrolytes that are compatible with micro-sized silicon anodes, enabling the battery to operate at higher voltages while maintaining excellent cycling stability and long-term durability. The use of silicon anodes significantly increases the energy density of the battery, making it ideal for next-generation electric devices and vehicles that require high energy outputs and fast charging capabilities.

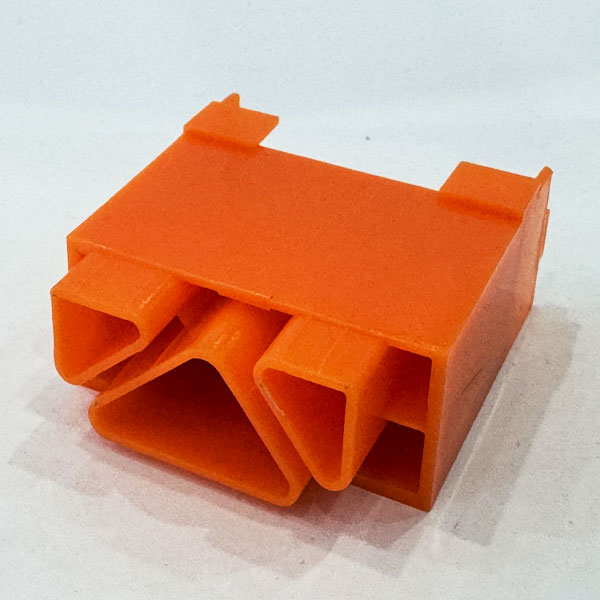

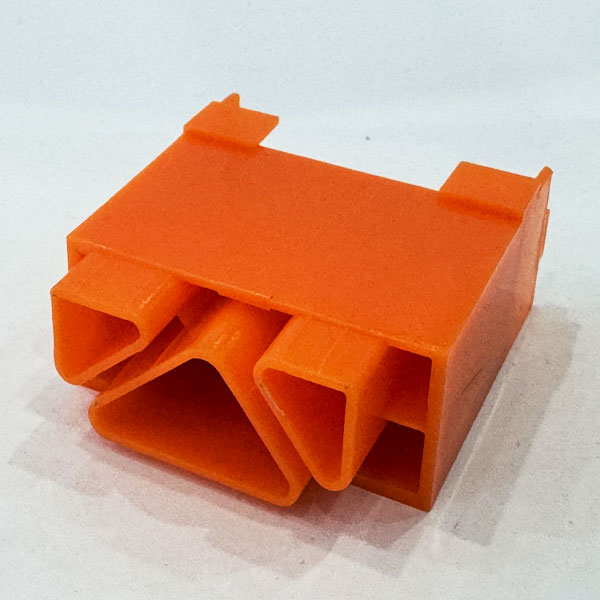

Additionally, the system incorporates a robust battery locking device and a quick-change interface, allowing for rapid assembly and disassembly of the power battery. This feature not only facilitates efficient battery replacement but also supports the logistics of battery swapping stations, which are becoming increasingly important in the expanding EV infrastructure.

Moreover, the product is equipped with a braking energy recovery system that captures and stores the kinetic energy generated during braking, converting it back into electrical energy for reuse. This not only improves overall efficiency but also extends the driving range of electric vehicles.

In summary, Arida New Energy's Power Battery High Voltage Extraction Support represents a significant advancement in battery technology, offering enhanced performance, safety, and convenience for high-voltage applications in the rapidly growing field of renewable energy and electric mobility."