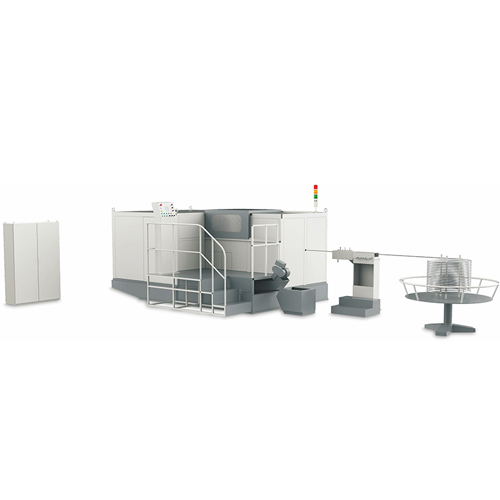

7-MOLD 7-PUNCH Cold Forming Machine

A cold former is a vital tool for fastener manufacturers, offering high production rates, precision, and cost-effectiveness. By investing in a cold former, companies can significantly enhance their production capabilities, ensuring they meet the demands of various industries with high-quality, consistent fasteners. Regular maintenance, proper training, and adherence to safety standards are key to maximizing the benefits of these machines.

Understanding the work principle of a bolt former is crucial for appreciating its efficiency and precision in manufacturing bolts and other fasteners.