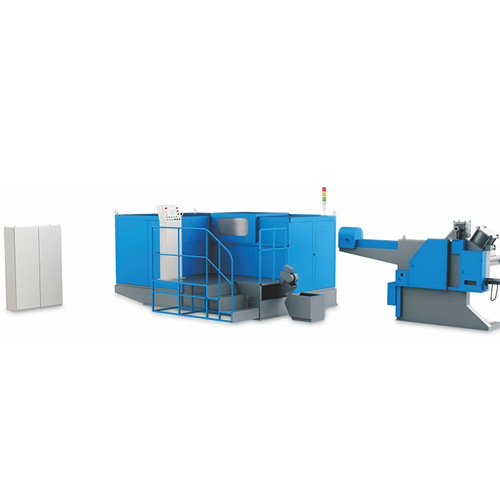

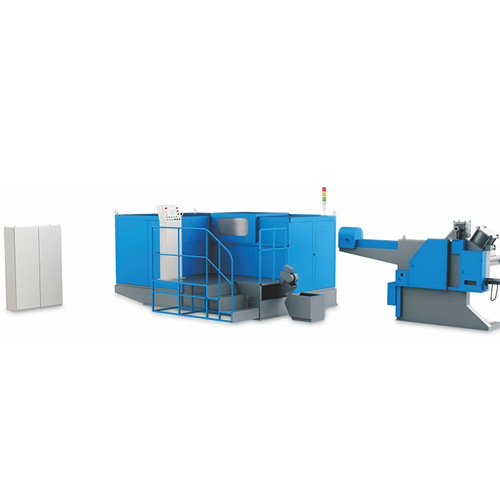

6-MOLD 6-PUNCH Cold Forming Machine

A cold former is a vital tool for fastener manufacturers, offering high production rates, precision, and cost-effectiveness. By investing in a cold former, companies can significantly enhance their production capabilities, ensuring they meet the demands of various industries with high-quality, consistent fasteners. Regular

maintenance, proper training, and adherence to safety standards are key to maximizing the benefits of these machines.

Cold forming can improve the mechanical properties of the material, such as tensile strength and fatigue resistance, because the material is not subjected to the thermal stresses associated with hot forming. The process aligns the grain structure of the metal, which enhances the part's strength and durability.

General Information

Q1: What is a bolt former?A1: A bolt former, also known as a cold heading machine, is a specialized piece of equipment used to manufacture bolts and other fasteners. It shapes metal at room temperature using high pressure, which allows for the production of high-quality, consistent bolts with improved mechanical properties.

Q2: How does a bolt former work?A2: A bolt former operates by feeding a metal wire or rod through a series of dies and punches. The wire is cut to the desired length and then shaped into the final bolt form using high pressure. The process typically includes steps such as cutting, heading (forming the head), and threading (if required). The entire process is controlled by advanced systems like PLCs (Programmable Logic Controllers) or CNC (Computer Numerical Control) to ensure precision and efficiency.

Machine Types and Capabilities

Q3: What are the different types of bolt formers?A3: There are several types of bolt formers, including:

Single-Stage Cold Formers: Perform one operation, such as cutting or heading, in a single station.

Multi-Stage Cold Formers: Perform multiple operations (cutting, heading, threading) in a series of stations, reducing the need for secondary operations.

Combination Cold Formers: Integrated machines that can perform multiple operations in one setup, often with additional features for flexibility.

Q4: What materials can a bolt former handle?A4: Bolt formers can handle a wide range of materials, including:

Carbon steel

Stainless steel

Alloy steel

Brass

Bronze

Aluminum

Titanium

Q5: What sizes of bolts can a bolt former produce?A5: Bolt formers can produce bolts in various sizes, typically ranging from small diameters (e.g., 1mm) to larger diameters (e.g., 20mm or more), and lengths up to several inches. The specific size range depends on the machine model and its capabilities.

Operation and Maintenance

Q6: How do I set up a bolt former?A6: Setting up a bolt former involves several steps:

Material Preparation: Ensure the raw material (wire or rod) is clean and free of defects.

Feeding System: Set up the coil feeder and straightener to supply the material smoothly.

Tooling Installation: Install the appropriate dies and punches for the desired bolt size and shape.

Programming: Program the machine using the HMI (Human-Machine Interface) to set the parameters for the specific job.

Test Run: Conduct a test run to ensure everything is working correctly and adjust settings as needed.

Q7: How do I maintain a bolt former?A7: Regular maintenance is crucial for the optimal performance of a bolt former:

Lubrication: Regularly lubricate moving parts to reduce wear and friction.

Inspection: Check for wear and tear on critical components, such as dies, punches, and guides.

Cleaning: Keep the machine and its components clean to prevent contamination and ensure smooth operation.

Professional Servicing: Schedule periodic professional servicing to address any issues and perform in-depth maintenance.

Q8: What are common issues with bolt formers and how can they be resolved?A8: Common issues include:

Wear and Tear: Replace worn dies and punches regularly.

Material Defects: Ensure the raw material is of high quality and free of defects.

Misalignment: Check and adjust the alignment of dies and punches.

Machine Settings: Verify and adjust machine settings for the specific job.

Noise and Vibration: Check for loose parts and tighten them as needed.

Performance and Efficiency

Q9: What is the production rate of a bolt former?A9: The production rate of a bolt former can vary depending on the machine model and the complexity of the part. Typically, high-speed bolt formers can produce between 100 to 400 pieces per minute.

Q10: How does a bolt former ensure precision and consistency?A10: Bolt formers ensure precision and consistency through:

Advanced Control Systems: PLCs and CNC systems provide precise control over the forming process.

High-Quality Tooling: Using high-precision dies and punches.

Regular Calibration: Regularly calibrating the machine to maintain accuracy.

Quality Control: Implementing quality control measures to inspect and test the produced bolts.

Safety and Compliance

Q11: What safety measures should be taken when operating a bolt former?A11: Safety measures include:

Training: Ensure all operators are properly trained and understand the machine's operation and safety protocols.

Personal Protective Equipment (PPE): Use safety glasses, ear protection, and appropriate clothing.

Machine Guards: Keep all guards and safety devices in place and functioning.

Regular Inspections: Conduct regular inspections to identify and address potential hazards.

Q12: What regulations and standards should bolt formers comply with?A12: Bolt formers should comply with industry standards such as:

ISO (International Organization for Standardization)

OSHA (Occupational Safety and Health Administration)

CE Marking (European Union)

ANSI (American National Standards Institute)

Cost and Investment

Q13: What is the cost of a bolt former?A13: The cost of a bolt former can vary widely depending on the type, size, and features of the machine. Single-stage cold formers are generally less expensive, while multi-stage and combination cold formers can be more costly. Prices can range from tens of thousands to hundreds of thousands of dollars.

Q14: What are the long-term benefits of investing in a bolt former?A14: Long-term benefits include:

Increased Production Efficiency: Higher production rates and reduced labor costs.

Improved Quality: Consistent and high-quality bolts with tight tolerances.

Material Savings: Reduced material waste through precise forming processes.

Versatility: Ability to handle a wide range of materials and sizes.

Competitive Advantage: Enhanced capability to meet customer demands and expand market share.

Additional Resources

Q15: Where can I find more information about bolt formers?A15: For more information, you can:

Contact Manufacturers: Reach out to leading manufacturers of bolt formers for detailed specifications and support.

Industry Associations: Join industry associations for resources, training, and networking opportunities.

Technical Literature: Read technical literature, journals, and online resources focused on fastener manufacturing.