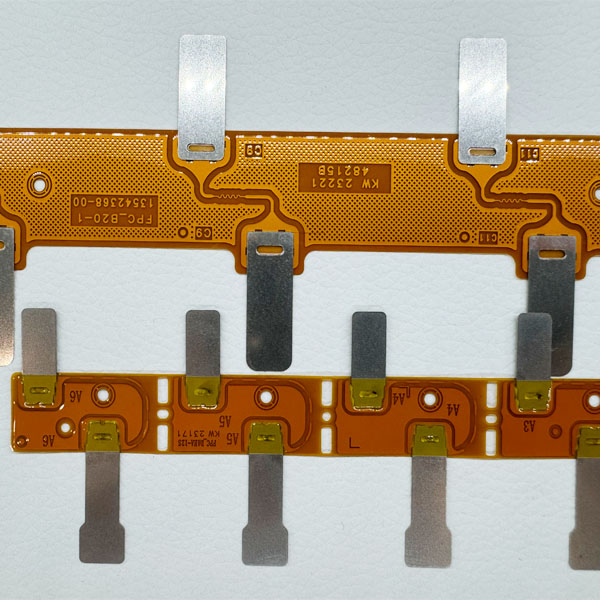

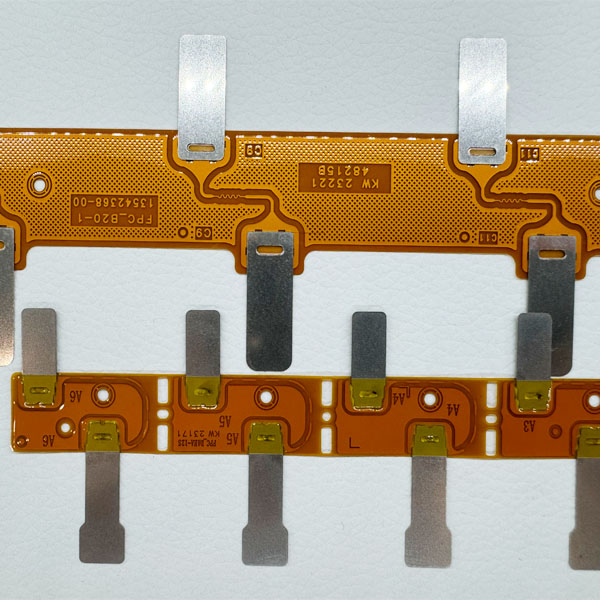

CCS Spot Welding Tape Mickel Plated Steel Nickel Sheet

CCS (Current Collector Strip) spot welding tape nickel-plated steel nickel sheet is a specialized conductive material used in the assembly of battery cells, particularly in lithium-ion and nickel-based batteries. This material consists of a steel core that is coated with a layer of nickel to enhance its electrical conductivity and corrosion resistance. The nickel-plated steel serves as a current collector, connecting the positive electrode (cathode) of a battery cell to the external circuit. The tape format allows for easy handling and application during the manufacturing process, and its suitability for spot welding ensures secure and consistent connections between the battery cells and the current collector. This material is optimized for high-performance and reliable battery systems, offering a balance of strength, conductivity, and cost-effectiveness.