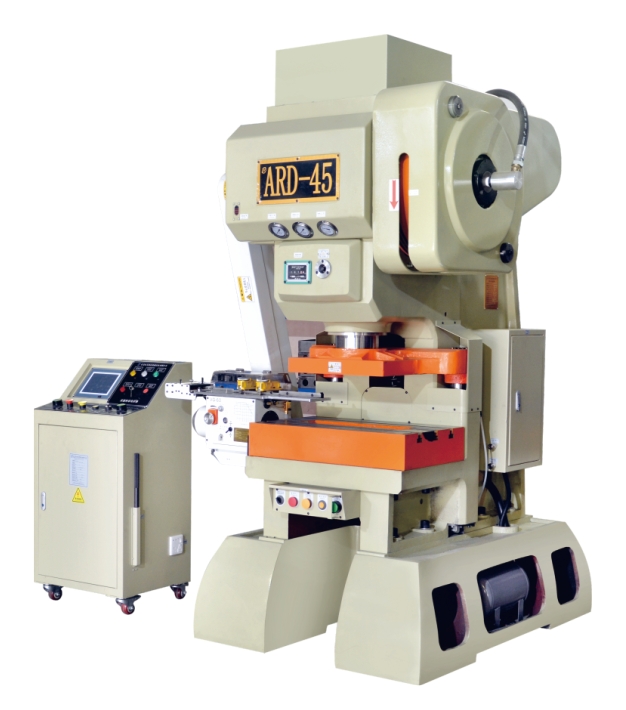

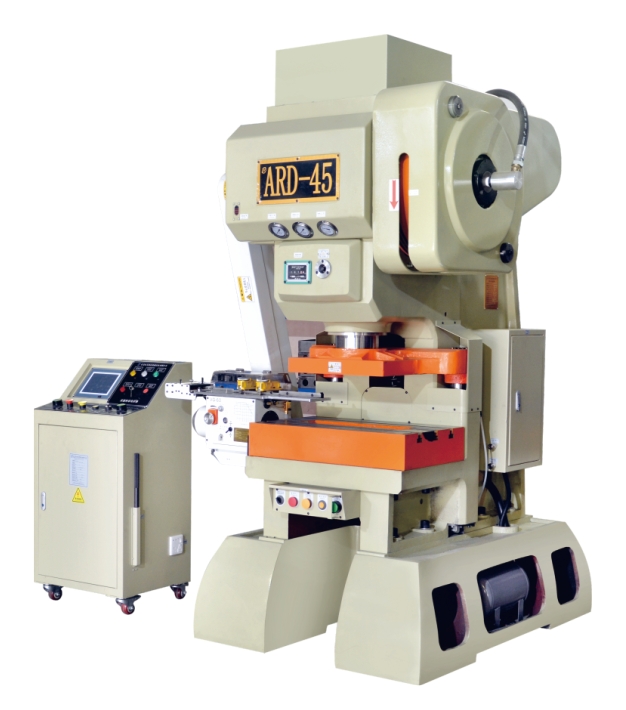

Machine Introduction

High Speed C-45T Press Machine

ARIDA C-45T High-Speed Press is a highly efficient and versatile machine designed specifically for precision metal stamping operations. With a maximum tonnage capacity of 45 tons, this press is well-suited for a variety of applications ranging from intricate electronic components to durable hardware pieces. Its compact design makes it ideal for workshops where space is a premium, yet it delivers exceptional performance and accuracy.

The C-45T is equipped with advanced technology, including a high-speed servo motor that provides precise control over the stroke length and speed, enabling consistent and high-quality production even at fast cycle rates. The press's rigid construction ensures minimal deflection during operation, which contributes to the longevity and reliability of the machine.

Safety is a top priority in the design of the C-45T, and it includes several features such as light curtains and emergency stop buttons to protect operators from potential hazards. Additionally, the user-friendly interface simplifies the setup and operation process, allowing operators to quickly adjust settings for different jobs and ensuring smooth transitions between production runs.

Maintenance is also streamlined with easy access to key components, reducing downtime and increasing productivity. The C-45T is a reliable solution for manufacturers looking to enhance their production capabilities without compromising on quality or safety standards.

Advantages of the C-Type 45-Ton High-Speed Press Machine

A C-type 45-ton high-speed press is a versatile and robust metalworking machine designed to offer several key advantages over other types of presses. Here are some of the benefits:

Compact and Rigid Construction: The C-frame construction provides a compact footprint while maintaining high rigidity, making it suitable for smaller workspaces without compromising on performance.

High Speed: With its optimized mechanical design and powerful motor, this type of press can achieve very high stamping speeds, which significantly increases productivity and throughput.

Precision and Accuracy: The rigid frame and precise guiding system ensure accurate and consistent part production, meeting tight tolerances required by many applications.

Versatility: A C-type 45-ton high-speed press can handle a wide range of materials and processes, including blanking, piercing, forming, and embossing, making it ideal for various manufacturing needs.

Ease of Operation: The machine typically features user-friendly controls and interfaces, allowing operators to quickly set up and run the press with minimal training.

Cost-Effectiveness: Despite its higher capacity, the initial investment and ongoing operating costs are generally lower compared to larger presses, making it a cost-effective solution for medium-duty applications.

Maintenance-Friendly: The open C-frame design facilitates access to internal components, making routine maintenance and repairs more straightforward and quicker.

Safety Features: Modern C-type presses often come equipped with safety devices like light curtains and interlocked guards, which help protect operators from potential hazards.

Energy Efficiency: Advanced drive systems and energy-saving technologies reduce power consumption, contributing to cost savings and environmental sustainability.

These attributes make the C-type 45-ton high-speed press a valuable addition to any manufacturing facility looking to improve efficiency and maintain high-quality standards.

Features of the High Speed C-45T Press Machine

Compact Design:

High Speed Capabilities:

45-Ton Capacity:

Precision Control:

Versatile Tooling:

Energy Efficiency:

Safety Features:

Durability:

Typical Applications of the High Speed C-45T Press Machine

Automotive Industry:

Electronics Manufacturing:

Appliance Manufacturing:

Aerospace Components:

Medical Devices:

General Metalworking:

Prototyping:

Custom Fabrication:

The High Speed C-45T Press Machine is a versatile tool that offers manufacturers a combination of speed, precision, and adaptability, making it a valuable asset in various industries where high-quality metal components are needed.

High Speed C-45t Press Machine Specification

FAQ

What is the typical application range for a C-type 45-ton high-speed press?

Answer: A C-type 45-ton high-speed press is commonly used for a variety of metalworking applications, including blanking, piercing, forming, and embossing. It is suitable for medium-duty tasks and can handle a wide range of materials, such as sheet metals and thin-gauge materials.

What are the key features that make a C-type 45-ton high-speed press stand out?

Answer: Key features include a compact and rigid C-frame construction, high-speed capabilities, precision guidance systems, easy-to-use controls, and built-in safety features. These features combine to provide high accuracy, efficiency, and operator safety.

How does the C-type 45-ton high-speed press compare to larger presses in terms of cost and performance?

Answer: While larger presses can handle heavier loads and thicker materials, a C-type 45-ton press offers a more cost-effective solution for medium-duty applications. It typically has a lower initial investment and operating costs, while still providing high performance and reliability.

What kind of maintenance is required for a C-type 45-ton high-speed press?

Answer: Regular maintenance includes lubrication of moving parts, checking and replacing wear items like seals and bearings, and cleaning the machine to prevent debris buildup. Routine inspections should be conducted to ensure all safety features are functioning correctly.

Are there specific safety measures that should be taken when operating a C-type 45-ton high-speed press?

Answer: Yes, safety is crucial. Operators should receive proper training and always follow the manufacturer's guidelines. Common safety measures include using light curtains or other presence-sensing devices, wearing appropriate personal protective equipment (PPE), and ensuring that all safety guards and interlocks are in place and functioning properly.