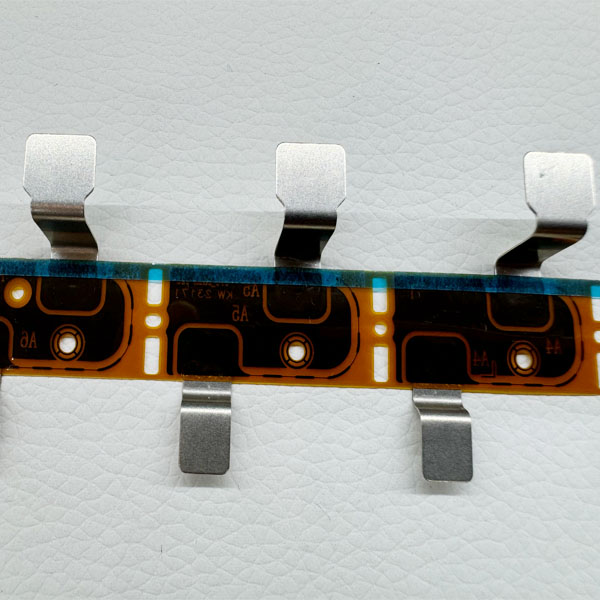

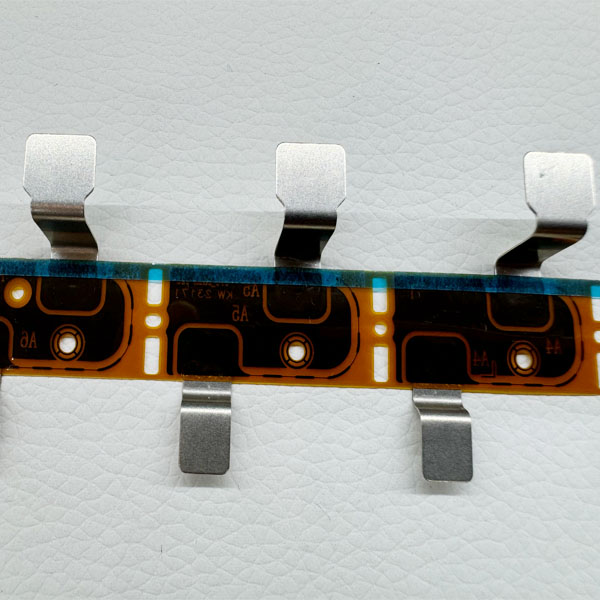

Custom CCS Cell Pure for Nickel Cadmium Battery

Custom CCS Cell Pure for Nickel Cadmium Battery

Battery nickel strips, also known as nickel tabs or nickel sheets, are key components in the construction of rechargeable batteries, particularly in lithium-ion and nickel-based battery technologies. These strips are typically made of pure nickel due to its excellent electrical conductivity, corrosion resistance, and ability to withstand the harsh chemical environment within a battery. Here are some of the key advantages and features of battery nickel strips:

High Electrical Conductivity: Nickel has high electrical conductivity, which is crucial for efficient current transfer between the battery's electrodes and the external circuit.

Corrosion Resistance: Nickel is highly resistant to corrosion, making it suitable for long-term use in the corrosive environment of a battery.

Durability: Nickel strips are durable and can withstand the mechanical stresses and strains that occur during the charging and discharging cycles of a battery.

Thermal Stability: Nickel maintains its structural integrity at high temperatures, ensuring stable performance even under demanding conditions.

Compatibility: Nickel strips are compatible with a wide range of battery chemistries, making them a versatile choice for different types of rechargeable batteries.

Customizability: Battery nickel strips can be customized in terms of size, thickness, and shape to fit specific battery designs and performance requirements.

These features make battery nickel strips an essential component in ensuring reliable and efficient current collection and distribution in rechargeable batteries, contributing to their overall performance and longevity.