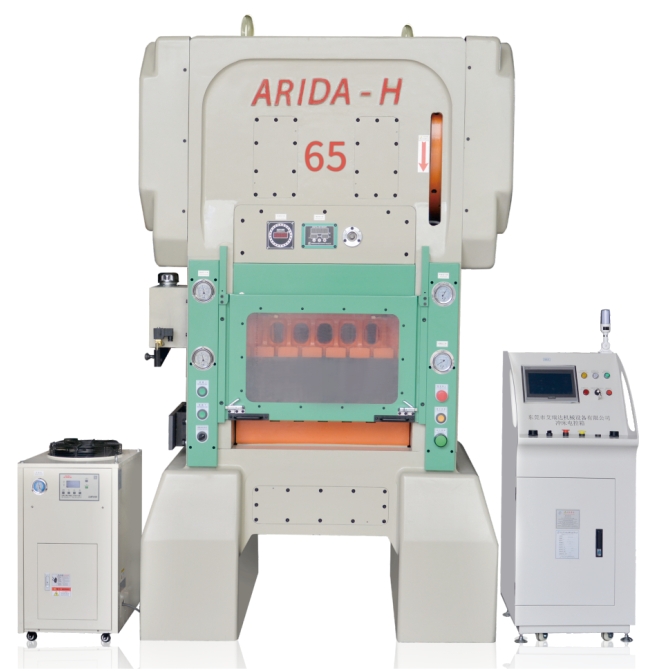

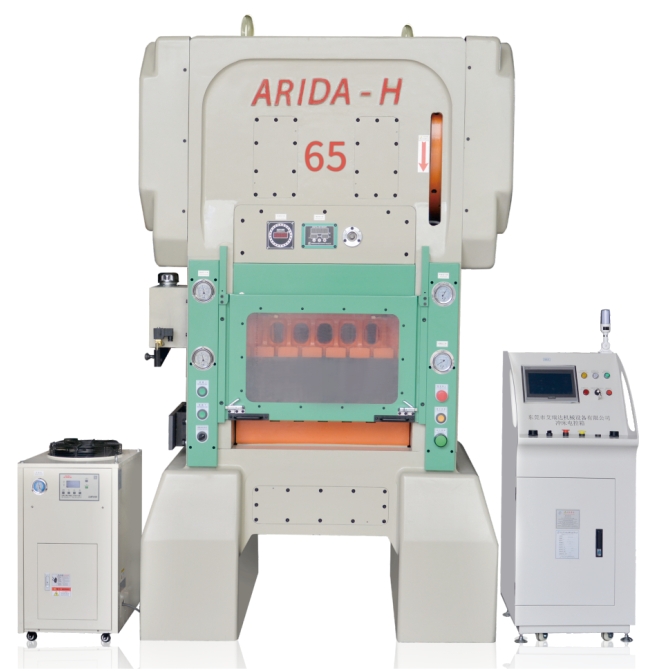

Machine Introduction

High Speed H-65T Press Machine

ARIDA H-type 65-ton high-speed press machine offers several key advantages that make it an excellent choice for various manufacturing applications. Firstly, its robust H-frame design ensures superior stability and durability, making it suitable for heavy-duty operations. The high-speed capability allows for increased productivity by processing parts at a faster rate compared to conventional presses. Additionally, this model typically features advanced control systems, which provide precise and consistent performance, ensuring high-quality output. Its compact design also contributes to space efficiency on the factory floor, while the low maintenance requirements help reduce operational costs over time. Furthermore, the H-type press is often equipped with safety features such as light curtains and emergency stop buttons, ensuring operator safety and compliance with industry standards."

High Speed Press Machine H-65T Features

The H-type 65-ton high-speed press machine is designed with several distinctive features that make it ideal for precision metal forming applications. Its H-frame construction provides exceptional rigidity and stability, minimizing deflection during operation. This machine is capable of delivering up to 65 tons of force at high speeds, enabling efficient production of intricate and complex parts. It typically incorporates advanced servo technology or a direct-drive system, which ensures precise control over the stroke length, speed, and position. The machine also features a user-friendly interface for easy programming and operation, along with built-in safety mechanisms like light curtains and emergency stop functions to protect operators. Additionally, its modular design allows for easy maintenance and upgrades, ensuring long-term reliability and adaptability in various industrial settings。

Applications and Industries for High-Speed Press Machines

The H-type 65-ton high-speed press machine is widely utilized across various industries due to its versatile capabilities. In the automotive sector, it is employed for the rapid production of intricate components such as brackets, fasteners, and body parts, thanks to its high-speed operation and precision. In the electronics industry, this type of press is used for stamping delicate metal parts like connectors, clips, and terminals, where accuracy and consistency are critical. Aerospace manufacturers also benefit from the H-type press, using it for the fabrication of lightweight yet strong components necessary for aircraft. Additionally, the machine finds applications in the production of household appliances, where it can form sheet metal into complex shapes for parts like refrigerator panels, washing machine drums, and air conditioner components. Its compact footprint and high efficiency make it suitable for both large-scale manufacturing plants and smaller facilities requiring high-volume production.

High Speed H-65t Press Machine Specification

| Model | Arida-65

|

Capacity

| 65 Ton

|

Stroke of Slide

| 35mm 40mm 45mm 50mm

|

SPM

| 200-750

|

Die-Shut height

| 200-250mm

|

Area of Slide

| 1100 x 700 x 150 mm

|

Slide

| 1100 x 480 mm

|

Slide Adjustment

| 40mm

|

Bed Opening

| 1000 x 150 mm

|

Motor

| 30 HP

|

Lubrication

| forced lubrication

|

Vibration System

| dynamic balance & shock-proof footpads

|

Our Service

Installation and Setup:

Operator Training:

Technical Support:

Regular Maintenance:

Spare Parts Supply:

Warranty and Repair Services:

Upgrade Options:

Customer Feedback Loop:

Documentation and Resources:

Detailed user manuals and technical documentation.

Access to online resources, including FAQs and troubleshooting guides.

Lifetime Support:

FAQ

Q: What is the maximum tonnage of the H-type 65-ton high-speed press?A: The maximum tonnage of the H-type 65-ton high-speed press is 65 tons, which refers to the maximum force it can apply during the pressing operation.

Q: What materials can be processed using this machine?A: This machine is suitable for processing a wide range of materials including mild steel, stainless steel, aluminum, and other non-ferrous metals. It is commonly used for applications such as blanking, piercing, forming, and deep drawing.

Q: How does the H-type frame contribute to the machine's performance?A: The H-type frame design provides superior rigidity and stability, which minimizes deflection during high-speed operations. This results in higher precision and longer tool life.

Q: Can the machine handle high-speed operations?A: Yes, the H-type 65-ton high-speed press is specifically designed to operate at high speeds, allowing for increased productivity and efficient part production.

Q: Is the machine easy to maintain?A: Yes, the H-type 65-ton high-speed press typically features a modular design that facilitates easy access for maintenance and repairs, reducing downtime and maintenance costs.