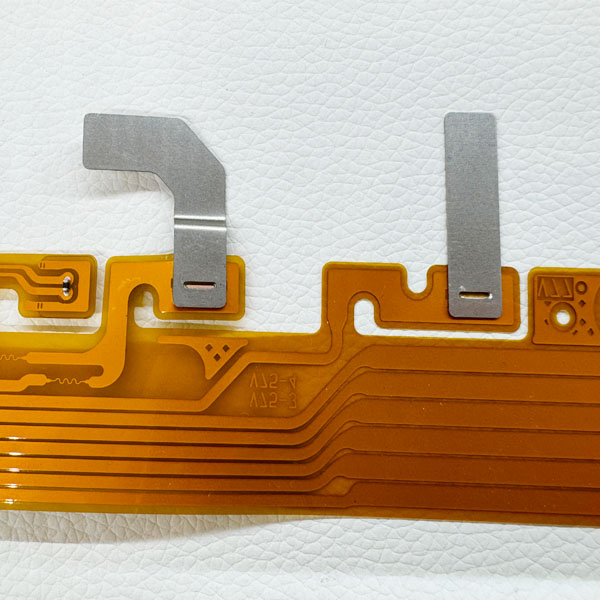

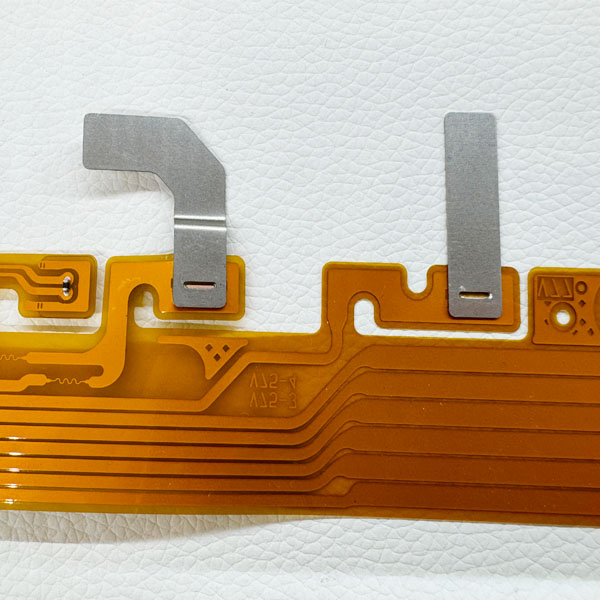

Strip Welding Connector Pure Nickel Sheet for Battery

Battery nickel strips, also known as nickel tabs or nickel sheets, are metallic components used in the construction of rechargeable batteries, particularly in lithium-ion and nickel-based battery technologies. These strips are typically made of pure nickel due to its excellent electrical conductivity, corrosion resistance, and ability to withstand the harsh chemical environment within a battery. Nickel strips serve as current collectors, connecting the active material of the battery cells to the external circuit. They are crucial for transferring electrical current efficiently between the battery's electrodes and the device being powered. Battery nickel strips come in various thicknesses and sizes to accommodate different battery designs and performance requirements.