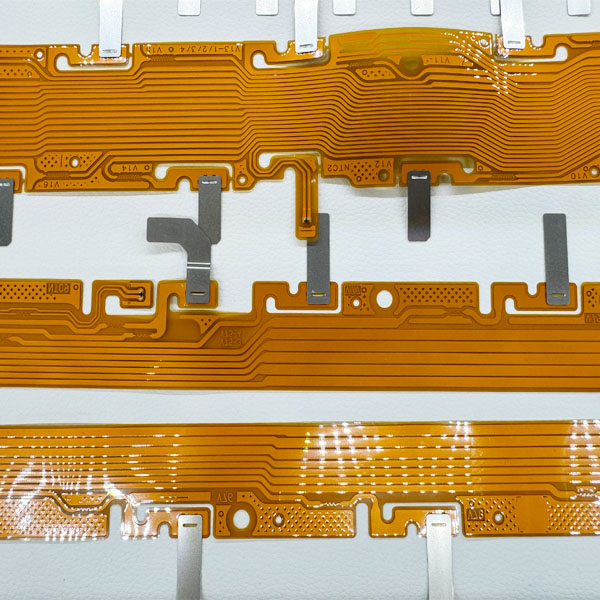

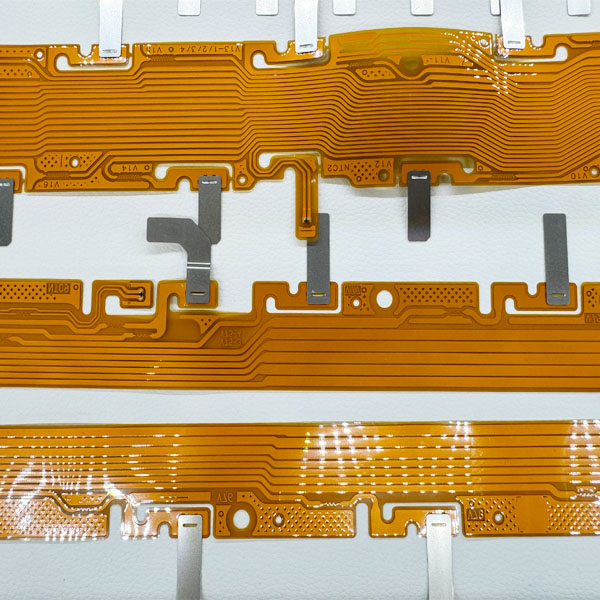

Nickel Plated Steel Strip Welding Belt for Battery

CCS battery nickel strips offer several key advantages for modern battery technologies. These specialized nickel tabs are designed for direct cell-to-cell connections, eliminating the need for intermediate modules or packs. This innovative design optimizes space usage, reduces weight, and enhances the overall energy density and performance of the battery system. The direct cell-to-cell connection also simplifies assembly and can result in more efficient and cost-effective battery production. CCS battery nickel strips are particularly beneficial in applications requiring high energy density and fast charging capabilities, such as electric vehicles (EVs), energy storage systems, and portable electronic devices. By improving electrical conductivity between cells and reducing internal resistance, these nickel strips contribute to longer battery life, faster charging times, and better overall performance.