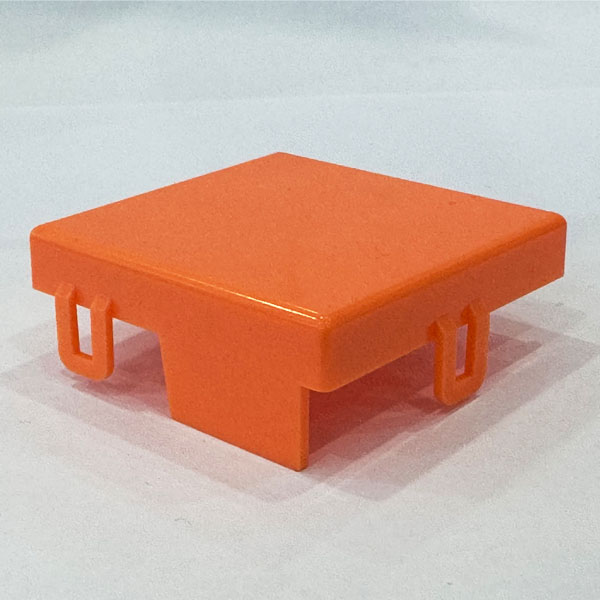

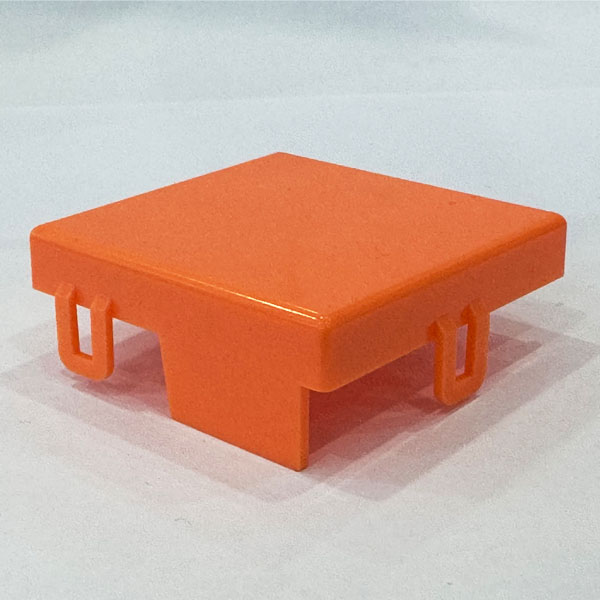

The Customized Injection Molding New Energy Power Battery Bronze Protective Cover is a precision-engineered component designed to provide structural support and protection for new energy power batteries. This protective cover is made using high-quality bronze materials and advanced injection molding techniques to ensure durability, reliability, and optimal fit. Its primary function is to safeguard the battery during installation, operation, and maintenance, while also facilitating efficient and secure battery extraction when needed. The cover can be customized to meet specific customer requirements, including size, shape, and additional features, making it a versatile solution for a variety of applications, such as electric vehicles and renewable energy storage systems.