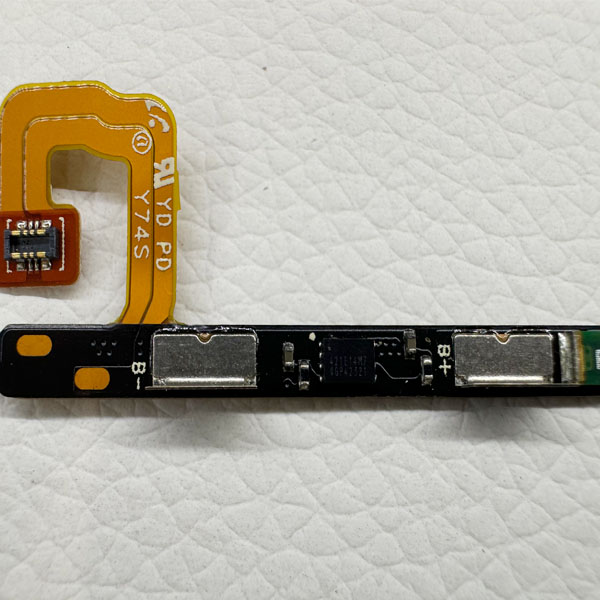

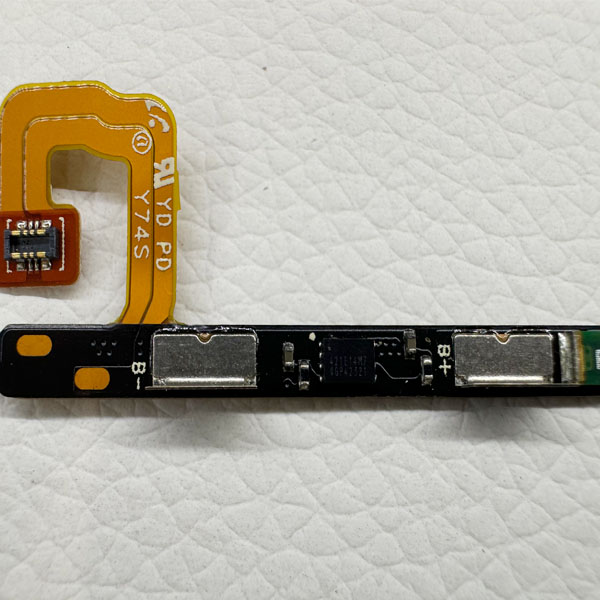

Aluminum Nickel Sheet Connector Steel Sheet for Battery

An Aluminum Nickel Sheet Connector Steel Sheet for Battery products refers to a specialized component used in the construction of battery packs, particularly in high-performance applications such as electric vehicles (EVs) and renewable energy storage systems. This component combines aluminum and nickel sheets with steel to create a robust and efficient electrical connection within the battery system.

The aluminum and nickel sheets are typically used for their excellent electrical conductivity and corrosion resistance, while the steel sheet provides additional strength and structural integrity. The connector is designed to facilitate the electrical connection between individual battery cells, ensuring a stable and low-resistance path for the flow of current.

These connectors often feature welding spots or tabs that are ultrasonically or laser welded to the battery cells, ensuring a secure and reliable bond. The combination of materials and design makes these connectors suitable for demanding applications where durability, efficiency, and safety are critical.