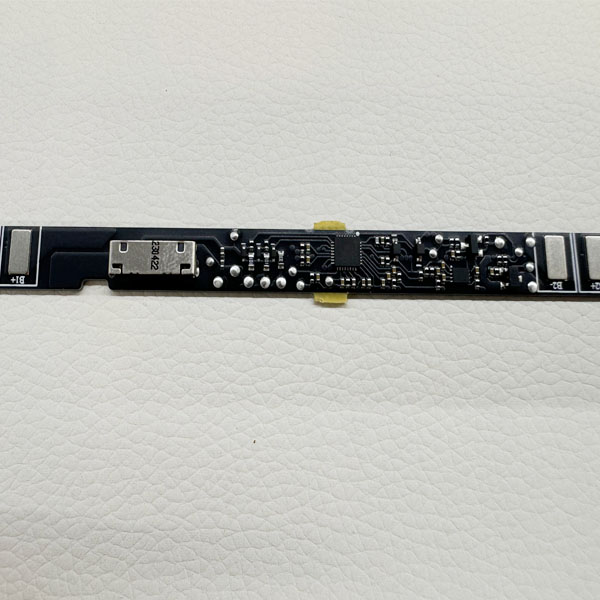

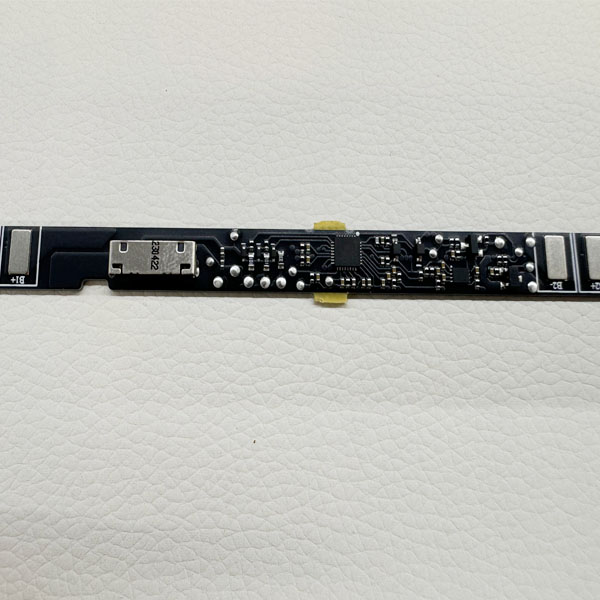

Adjustable Cell Spacing Customized Size for Nickel Sheet

Adjustable Cell Spacing Customized Size for Nickel Sheets refers to specialized nickel sheets that are designed and fabricated to precise dimensions and shapes to fit the specific requirements of a battery assembly. These nickel sheets are used as current collectors and connectors within battery packs, enabling the efficient flow of electrical current between individual cells. The adjustable cell spacing feature allows for the optimization of the battery pack design, accommodating various cell configurations and layouts to maximize performance and efficiency. The customization of size and spacing ensures a perfect fit and secure connection, contributing to the overall reliability and longevity of the battery system.