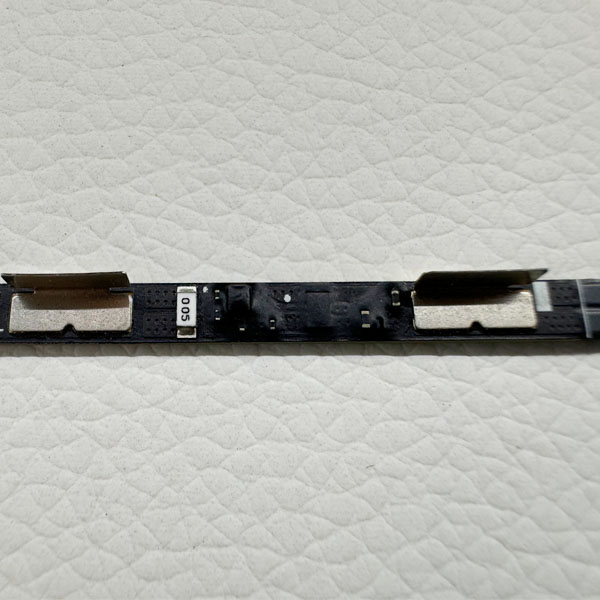

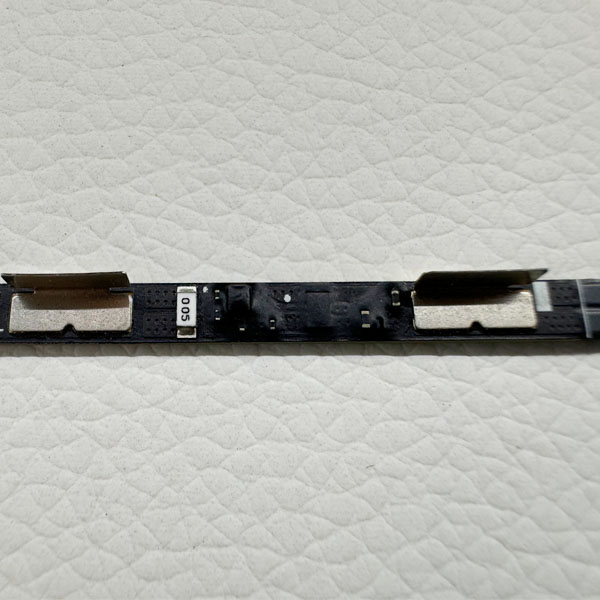

OEM Copper Connector Nicke Strip for Lithium Battery

An OEM (Original Equipment Manufacturer) Copper Connector Nickel Strip for Lithium Battery is a specialized conductive component used in the assembly of lithium-ion batteries. This component is typically made of a copper core that is plated with a layer of nickel to enhance its electrical conductivity and corrosion resistance. The nickel-plated copper strip serves as a current collector and connector, linking the positive or negative electrode of a battery cell to the external circuit. The strip is optimized for spot welding or other forms of attachment to the electrode, ensuring a secure and reliable electrical connection. This component is designed to meet the specific requirements and standards of the original equipment manufacturer, contributing to the overall performance and reliability of the lithium battery system.