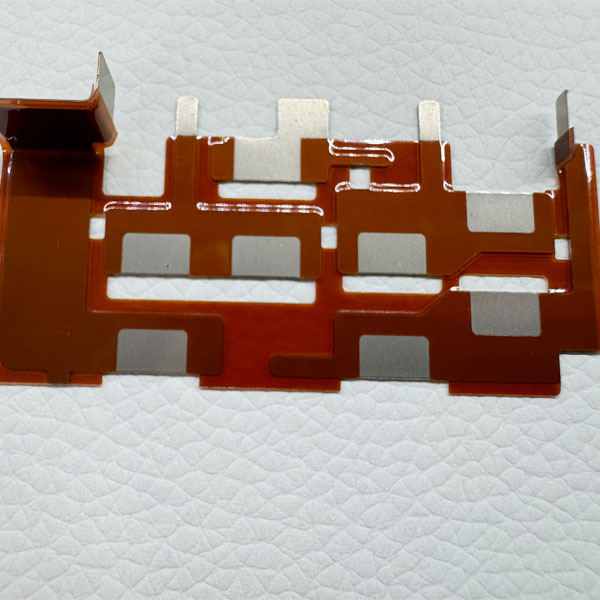

Nickel Sheet Soldering Tabs with Welding Spot Battery

Nickel Sheet Soldering Tabs with Welding Spot Battery products refer to a specialized component used in the assembly of battery packs, particularly in rechargeable battery systems such as those found in electric vehicles, consumer electronics, and energy storage solutions. These tabs are made from thin sheets of nickel, a material chosen for its excellent electrical conductivity, thermal stability, and resistance to corrosion.

Each tab is designed with specific welding spots that are used to create a secure connection to the battery cells. These welding spots are typically created through ultrasonic or laser welding techniques, which ensure a strong and reliable bond between the tab and the cell. The tabs serve as a conduit for the flow of electricity, enabling the connection of individual battery cells within a pack and facilitating the attachment of external wiring or connectors.

In addition to their role in electrical connectivity, nickel sheet soldering tabs also play a crucial part in the thermal management of battery packs. Their high thermal conductivity helps in dissipating heat generated during charging and discharging cycles, contributing to the overall safety and longevity of the battery system.

Overall, Nickel Sheet Soldering Tabs with Welding Spot Battery products are essential components in modern battery technology, providing a robust and efficient means of electrical and thermal management within battery assemblies.