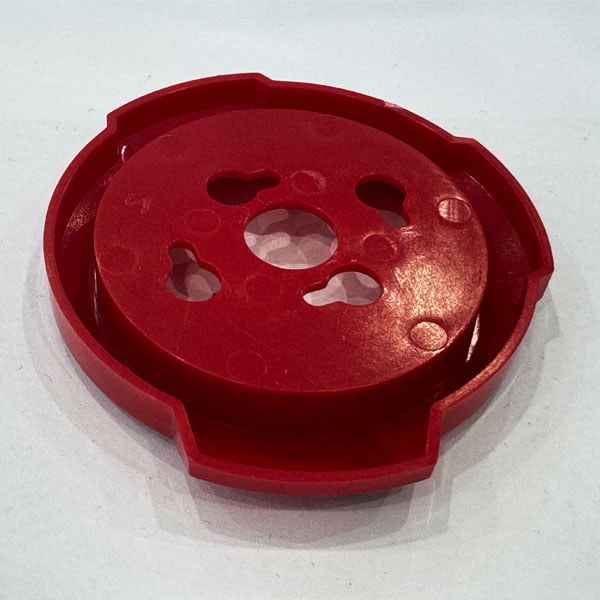

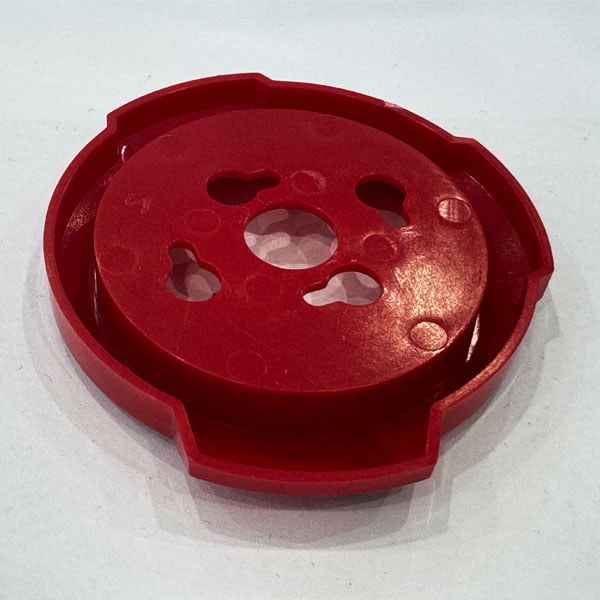

Custom Injection Molded Knob Assembly

A Custom Injection Molded Knob Assembly is a specialized component that is designed and manufactured to precise specifications for a particular application. This assembly typically consists of a knob, which is created using the injection molding process, where molten material—usually plastic—is forced into a mold cavity, cooled, and then ejected to form the desired shape. The knob can be attached to a shaft or another mechanical part to facilitate manual operation, such as turning, rotating, or adjusting equipment. Customization allows for variations in size, color, material, and even the inclusion of specific features like grip patterns or branding. The assembly may involve additional parts or processes to ensure the knob functions correctly within its intended system.

Knob base

With silk screen knob seat

Injection molded knob seat

Base with circuit knob board

Knob seat with light

Precision Engineering: Our knobs are designed using advanced CAD software, ensuring accurate fit and function.

Durability: Made from high-quality materials, these knobs offer long-lasting performance under various conditions.

Customizability: Choose from a variety of materials, colors, and finishes to match your brand or specific needs.

Ergonomics: Designed with user comfort in mind, our knobs provide an excellent grip and easy operation.

Integration: Easy to install and compatible with a wide range of applications, from industrial machinery to consumer electronics

Applications & Manfucturing Process

Our custom assemblies are versatile and find use in multiple sectors:

Consumer Electronics: Enhance the usability of devices such as audio equipment, cameras, and home appliances.

Industrial Controls: Improve the handling of manufacturing tools and machinery.

Medical Devices: Facilitate precise adjustments in medical equipment, contributing to better patient care.

Automotive Components: Contribute to the intuitive design of vehicle controls and interfaces.

Manufacturing Process:

Design Phase: We work closely with you to understand your requirements and create a detailed design using 3D modeling software.

Tooling: Once the design is finalized, we create the molds using high-grade steel or aluminum, ensuring durability and precision.

Injection Molding: Molten plastic is injected into the mold under pressure, forming the knob to exact specifications.

Post-Processing: After cooling, the parts undergo finishing processes such as trimming, polishing, and quality checks.

Assembly: The finished knobs are then assembled with any necessary hardware or additional components.

Quality Assurance: Each assembly undergoes rigorous testing to ensure it meets all functional and aesthetic standards.

Q: Can I customize the color of the knob?

A: Yes, we offer a range of color options to suit your specific needs or brand identity.

Q: What materials do you use for the knobs?

A: We primarily use durable plastics, but we can also incorporate other materials based on your requirements.

Q: How long does the production process take?

A: Production timelines vary depending on the complexity of the design and the quantity ordered. We will provide you with an estimated timeline upon order placement.

Q: Do you offer after-sales support?

A: Absolutely, we are committed to providing ongoing support to ensure your satisfaction with our products.