Custom Injection Molding Knob Seat for Industrial Use

A Custom Injection Molding Knob Seat for Industrial Use is a specially designed component fabricated using the injection molding process to serve as a base or mounting point for knobs in various industrial applications. This component is typically customized according to the specific requirements of the end-use, which might include factors such as size, material composition, strength, and compatibility with the knob and the overall system it is integrated into. The injection molding process involves heating raw materials, usually thermoplastics, to a molten state and injecting them into a mold cavity under high pressure. Once cooled and solidified, the molded knob seat is removed from the mold and prepared for assembly. These seats are often found in industrial machinery, control panels, and equipment where they provide a secure and ergonomic interface for users to interact with the device.

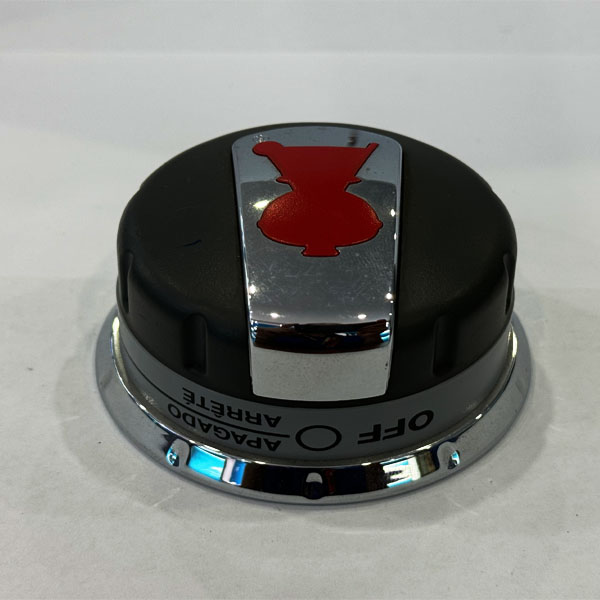

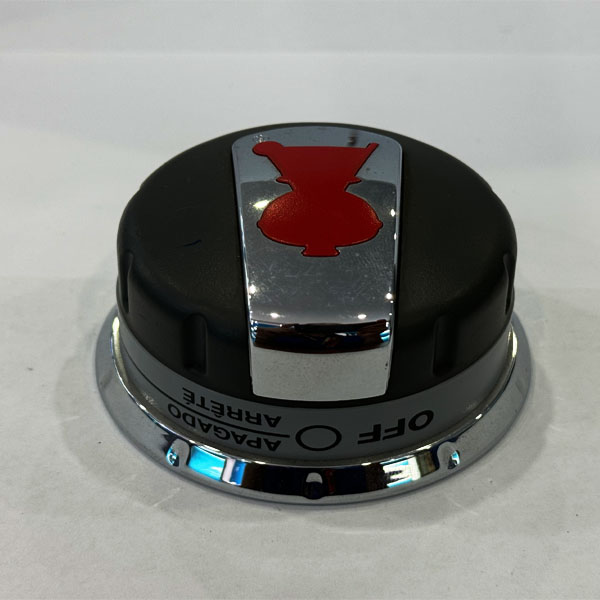

Knob assembly

Knob with silk screen printing

Injection molded red knob seat

Customization: Available in a variety of sizes, shapes, and materials to fit the exact requirements of your application.

Durability: Crafted from high-strength materials that withstand the rigors of industrial use, offering longevity and reliability.

Precision Fit: Engineered to ensure a perfect fit with your knobs, enhancing both functionality and user experience.

Ergonomics: Designed with comfort and ease of use in mind, promoting efficient operation and reducing user fatigue.

Compatibility: Compatible with a broad range of industrial equipment and systems, allowing for seamless integration.

Cost-Effective: Economical production methods make it possible to deliver high-quality components at competitive prices.

These custom knob seats find extensive use across multiple industries:

Manufacturing: Enhancing control over machinery and equipment in factory settings.

Automation: Improving interaction points in automated systems and robotics.

Instrumentation: Providing precise adjustment capabilities in scientific and measurement instruments.

Aerospace: Contributing to the functionality of cockpit controls and other critical systems.

Automotive: Enabling better interaction with vehicle controls and interfaces.

Design: Our engineering team collaborates with clients to develop detailed designs using CAD software, ensuring the knob seat aligns with the specific requirements.

Mold Making: Once the design is finalized, precision molds are created using high-grade steel to ensure accuracy and repeatability.

Injection Molding: Molten plastic is injected into the mold cavity under controlled conditions, forming the knob seat to the exact specifications.

Post-Processing: After cooling, the parts are trimmed, polished, and undergo a series of quality checks.

Assembly: The knob seats are then assembled with any additional components required for the final product.

Testing: Rigorous testing is conducted to ensure that the knob seats meet all performance and safety standards.

Q: Can I request a specific material for my knob seat?

A: Yes, we offer a range of materials, including various grades of plastic, to meet your specific needs.

Q: Are the knob seats customizable in terms of color?

A: Absolutely, we can produce knob seats in a variety of colors to match your branding or design preferences.

Q: How long does it take to manufacture custom knob seats?

A: The lead time varies depending on the complexity of the design and the quantity ordered. We will provide an estimate upon receiving your specifications.

Q: Do you offer assistance with the design phase?

A: Yes, our experienced design team can assist you in developing the optimal design for your knob seat.

Q: Is there a minimum order quantity?

A: While we do have standard MOQs, we are flexible and can discuss options that best suit your requirements.