In modern battery pack assembly, nickel parts stamping plays an essential role in creating high-performance components that ensure the efficiency, durability, and safety of batteries. Nickel sheets, nickel strips, and nickel taps are some of the most commonly used materials in these systems. These parts, manufactured through custom nickel parts stamping, provide the necessary conductivity and mechanical strength for battery systems, particularly in applications such as electric vehicles (EVs), motorcycles, and power tools. Arida Machinery, a leader in precision nickel manufacturing, specializes in producing these components with exacting standards to meet the demands of energy storage systems worldwide.

This article delves into the essential types of nickel parts used in battery pack assembly, their functions, and the importance of customizing these parts to suit specific battery applications. With high-quality nickel strips, nickel sheets, and nickel taps produced by Arida Machinery, the components used in battery packs ensure reliable energy transfer and optimal performance in challenging environments.

Overview of Nickel Parts in Battery Pack Assembly

Battery pack assemblies require components that can handle high electrical loads, maintain structural integrity, and dissipate heat effectively. Nickel parts are particularly well-suited for these applications due to their excellent conductivity and resistance to corrosion. They are essential for ensuring the smooth operation of energy storage systems, from the initial charge to energy discharge.

In a typical battery pack, nickel components are used for a variety of purposes:

Conducting electrical energy between cells,

Connecting battery cells in series or parallel configurations,

Distributing current across the entire battery system.

Nickel parts are commonly used in:

Battery Management Systems (BMS) that monitor the performance of individual cells,

Busbars and connectors that link the battery cells to the vehicle’s electrical system,

Heat dissipation components that prevent overheating of the battery.

The precision and customization of nickel parts stamping enable manufacturers to create parts that perfectly fit these critical functions, providing battery packs with the reliability and performance needed to power modern technologies.

Types of Nickel Parts Stamped for Battery Applications

Nickel Sheets

Nickel sheets are used to produce large, flat components such as battery connectors, terminals, and busbars. These custom stamped nickel parts are critical for connecting the cells within a battery pack and ensuring efficient energy transfer.

Nickel sheets are chosen for their:

High conductivity, which ensures minimal energy loss as electricity flows between cells,

Corrosion resistance, which extends the lifespan of the battery pack by preventing degradation in harsh environments,

Mechanical strength, which allows the parts to handle the stresses imposed by constant charging and discharging.

Arida Machinery’s nickel sheet components are designed to meet the specific requirements of battery applications, ensuring that each part performs optimally in the battery system.

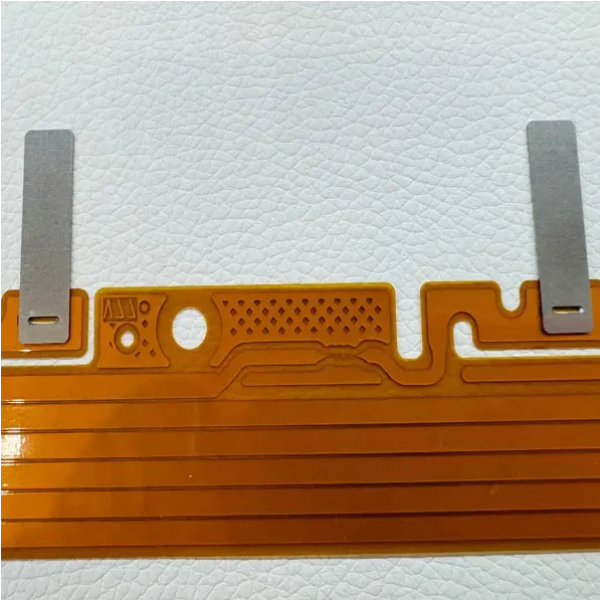

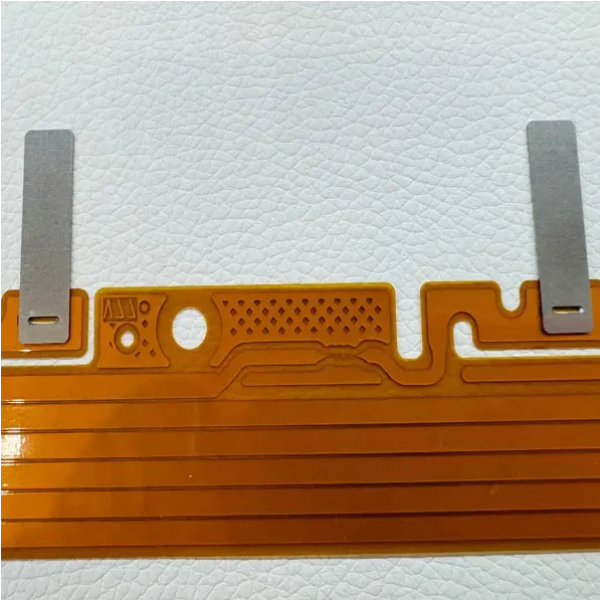

Nickel Strips

Nickel strips are utilized for more specialized applications within the battery pack, particularly as busbars and current conductors. These parts are used to link the individual cells in series or parallel, facilitating the efficient flow of electricity across the battery pack.

Key features of nickel strips include:

Thin and flexible design, allowing them to fit into tight spaces within battery packs,

Excellent conductivity, ensuring minimal resistance to the flow of electricity,

Customizable thickness and width, enabling the strips to meet the specific voltage and current requirements of the battery system.

Because of these qualities, nickel strips are used in applications requiring precision and flexibility, such as in the Battery Management System (BMS), where electrical connections between individual cells must be secure and efficient.

Nickel Taps

Nickel taps are small but crucial components used to connect individual battery cells in a series or parallel configuration. They are integral to maintaining the balance of electrical charge between the cells, ensuring that the battery pack operates safely and efficiently.

The advantages of nickel taps include:

Precision and reliability in creating electrical connections that can withstand high currents and voltages,

Custom design options, allowing the taps to be tailored to specific battery configurations,

Durability, as the nickel material resists corrosion and degradation over time.

In a battery pack, nickel taps ensure that each cell contributes to the overall system’s power while maintaining safety and balance.

Customization of Nickel Parts for Specific Battery Requirements

Each battery application requires customized solutions to meet specific operational needs. The thickness, size, and design of nickel parts can be adjusted to fit the unique requirements of different battery types, from large EV battery packs to compact power tool batteries.

Tailoring Nickel Sheets, Strips, and Taps for Different Applications

At Arida Machinery, we specialize in customizing nickel parts to suit the specific needs of our clients. Whether it's adjusting the thickness of nickel strips for high-voltage applications or customizing the size and shape of nickel sheets for connectors, our precision stamping process allows for a high degree of flexibility and accuracy.

For example:

Electric vehicle batteries require nickel strips with higher current-carrying capacity and specific dimensions to fit within the vehicle's battery design.

Power tool batteries may need nickel sheets and nickel taps that are more compact but still maintain the necessary conductivity and durability to handle repeated charging and discharging cycles.

By offering these custom solutions, Arida Machinery ensures that our nickel parts meet the exact specifications needed for the optimal performance of the final product.

Table: Comparison of Nickel Parts Used in Different Battery Applications

Part Type | Application | Key Properties |

Nickel Sheets | Used for large, flat components like battery connectors and terminals | High conductivity, durable, easy to form |

Nickel Strips | Used for busbars and current conductors | Flexible, excellent conductivity, customizable thickness |

Nickel Taps | Used for connecting battery cells in series/parallel | Strong, precise, reliable electrical connections |

Why Choose Custom Nickel Parts for Battery Packs?

Custom nickel parts stamping offers several advantages over off-the-shelf solutions, particularly in battery pack assembly, where precision and reliability are paramount.

Advantages of Custom Stamped Nickel Parts

Enhanced Performance: Custom parts are designed to meet the exact requirements of the battery system, ensuring that they contribute to the overall performance of the pack. This includes optimizing electrical conductivity, minimizing energy loss, and ensuring long-term durability.

Optimized Durability: Off-the-shelf parts may not be designed to withstand the specific environmental conditions of battery packs. Custom nickel parts are made to resist corrosion, thermal stress, and mechanical wear, all of which are common in energy storage applications.

Improved Safety: Battery packs must operate under strict safety conditions. Custom nickel parts ensure that all connections and components are secure, reducing the risk of failure and ensuring the battery operates safely under various conditions.

By opting for custom nickel parts stamping, manufacturers can optimize the performance, reliability, and safety of their battery systems, which is essential for industries like electric vehicles and energy storage.

Conclusion

Nickel parts stamping is a critical manufacturing process in the production of high-quality components for battery packs. By selecting the right materials, such as nickel sheets, nickel strips, and nickel taps, and customizing them to meet specific requirements, manufacturers can create battery systems that are reliable, efficient, and safe. Arida Machinery’s precision stamping process ensures that each custom stamped nickel part is crafted with the highest standards of quality, contributing to the overall success of the battery system.

If you are looking for customized nickel parts to enhance your battery system, contact us at Arida Machinery to explore our tailor-made solutions that meet your needs.

FAQ

1. What are the main types of nickel parts used in battery packs?

The main types of nickel parts used in battery packs are nickel sheets, nickel strips, and nickel taps, each serving a unique purpose in connecting and managing electricity within the pack.

2. Why is nickel used in battery pack assembly?

Nickel is highly conductive, durable, and resistant to corrosion, making it an ideal material for battery parts that need to handle high electrical loads and maintain long-term reliability.

3. How can nickel parts be customized for specific battery requirements?

Nickel parts can be customized in terms of thickness, size, and design to meet the exact needs of different battery applications, from electric vehicles to power tools.

4. What are the benefits of using custom-stamped nickel parts in battery packs?

Custom-stamped nickel parts ensure better performance, optimized durability, and enhanced safety in battery packs, which helps extend the lifespan and efficiency of the battery system.