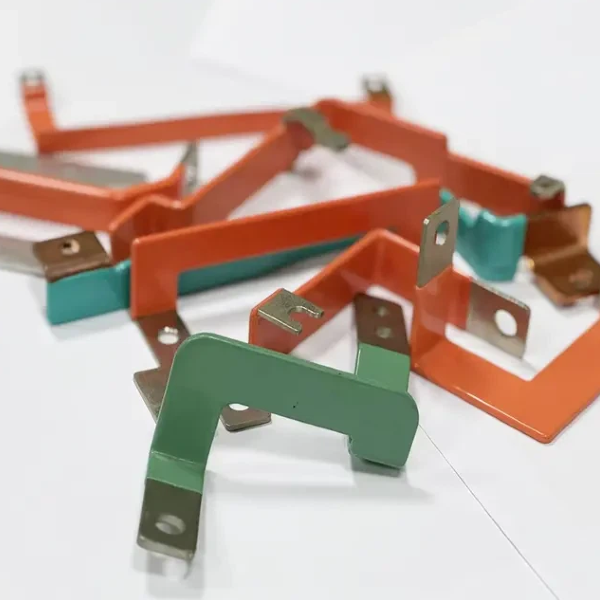

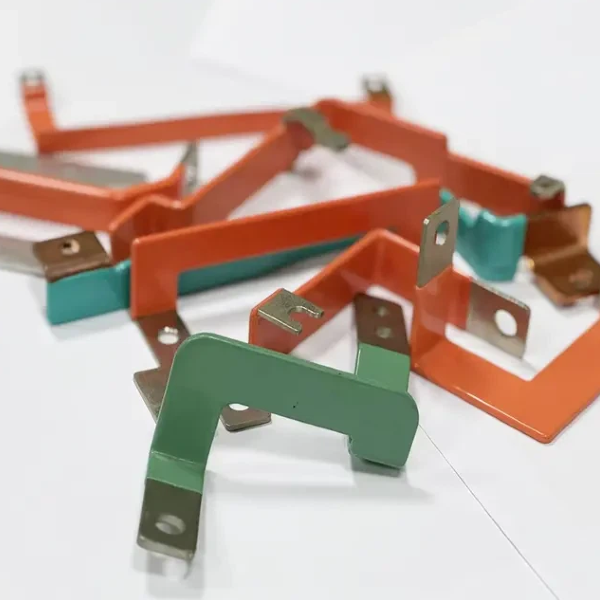

When assembling battery packs, particularly those used in electric vehicles (EVs) or energy storage systems, understanding the best practices and considerations when working with nickel parts stamping is crucial. Nickel sheet and custom nickel parts are integral components in ensuring the high performance, efficiency, and safety of battery systems. These nickel components need to be manufactured to meet strict standards, as they directly impact the overall functionality of the battery pack. At Arida Machinery, we specialize in providing precision nickel parts stamping solutions tailored to meet the specific needs of the battery industry. This article highlights the key considerations when using nickel parts stamping for battery assemblies, helping manufacturers understand the importance of material selection, overcoming common challenges, and adopting best practices.

The Importance of Material Selection in Nickel Parts Stamping

Choosing the right materials for nickel parts stamping is essential for ensuring the reliability and performance of battery systems. The materials used in the manufacturing process must meet various specifications, including electrical conductivity, corrosion resistance, and mechanical strength. These properties are critical in ensuring that battery packs function safely and efficiently in applications such as electric vehicles and power tools.

Nickel Sheets vs. Nickel Strips

Both nickel sheets and nickel strips are commonly used in battery assembly, but they serve different functions based on their form and application.

Nickel Sheets: These are flat, large sheets of nickel that are primarily used for creating battery connectors and terminals. Nickel sheets are ideal for parts that require high conductivity and can be shaped into flat, large components that handle electrical energy distribution across the battery cells.

Nickel Strips: These are thin, flexible pieces of nickel used primarily for busbars and current conductors. Nickel strips allow for easy bending and custom shapes to fit into tight spaces within the battery pack. They are particularly useful for connecting individual battery cells in series or parallel configurations.

Both materials are essential in battery pack assembly, but the choice between nickel sheets and nickel strips depends on the specific requirements of the battery system, such as the voltage and current load, available space, and design specifications.

Choosing the Right Nickel Alloys for Battery Applications

In addition to choosing the right form (sheet or strip), selecting the correct nickel alloy is another important consideration. Different alloys can significantly impact the performance and lifespan of battery systems. For example:

Nickel-copper alloys are often used in parts that require enhanced conductivity and resistance to corrosion.

Nickel-chromium alloys may be used in applications where resistance to high temperatures is crucial.

The alloy chosen must align with the specific demands of the battery pack, including operating temperature, electrical load, and environmental exposure (e.g., humidity, corrosion).

Common Challenges in Nickel Parts Stamping for Battery Assemblies

Despite the benefits of nickel parts stamping, there are several challenges associated with the process, especially when manufacturing parts for battery applications. These challenges must be addressed to ensure the final components meet the required standards.

Precision and Tolerance Control

One of the most significant challenges in nickel parts stamping is achieving the required precision and tolerance control. Battery components must meet very tight tolerances to ensure proper fit and function. Even small deviations can lead to significant issues in battery pack performance, such as poor electrical conductivity or mechanical failure.

At Arida Machinery, we use advanced precision stamping technology to ensure that every custom nickel part meets the exact specifications. Our equipment can handle a wide range of nickel thicknesses and produce parts with tolerances as low as 0.01mm, ensuring that each component fits perfectly into the final battery assembly.

Avoiding Material Defects

Another challenge in nickel parts stamping is ensuring that the nickel sheets used in the process are free from defects that could affect battery performance. These defects may include surface irregularities, cracks, or inconsistencies in thickness, all of which could compromise the conductivity or structural integrity of the final parts.

To minimize defects, Arida Machinery implements a comprehensive quality control process at every stage of production, from raw material inspection to final product testing. Our team of skilled technicians thoroughly inspects each batch of nickel sheets before they are stamped, ensuring that only high-quality material is used for battery components.

Best Practices for Ensuring High-Quality Nickel Parts

Rigorous Quality Control Processes

Ensuring the quality of nickel parts used in battery assembly requires rigorous quality control at every stage of the stamping process. From material inspection to final testing, each step is carefully monitored to ensure that the parts meet the highest standards.

Incoming Raw Materials Inspection: Before beginning the stamping process, nickel sheets are inspected for quality, including thickness, surface finish, and material composition.

In-Process Monitoring: During stamping, real-time monitoring systems are used to track factors such as pressure, temperature, and die alignment to ensure precision.

Final Product Testing: After stamping, each custom nickel part undergoes dimensional checks, visual inspections, and functional testing to ensure it meets the required specifications.

These quality control processes help ensure that every nickel part is free from defects and ready for integration into battery packs.

Collaborating with Experts for Custom Solutions

For battery manufacturers seeking to optimize the performance of their systems, working with experienced manufacturers like Arida Machinery is essential. We specialize in providing custom nickel parts that are tailored to meet the specific requirements of each application. Our team works closely with clients to understand their unique needs and develop solutions that improve performance, enhance safety, and increase durability.

Whether it’s designing custom nickel strips for high-voltage applications or creating specialized nickel sheets for battery connectors, Arida Machinery’s expertise in nickel parts stamping ensures that our clients receive the best possible components for their battery systems.

Table: Steps in the Nickel Parts Stamping Process

Step | Description | Quality Check |

Material Selection | Choose high-quality nickel sheets for stamping. | Incoming material inspection (thickness, finish) |

Stamping Process | Press nickel sheets into desired shapes. | Pressure, temperature, and die alignment checks |

Post-Processing | Deburr and finish the stamped parts. | Visual and dimensional inspection |

Final Product Testing | Test for conductivity and functionality. | Functional testing (e.g., electrical flow) |

The Role of Nickel Parts in Battery Safety and Efficiency

Properly stamped nickel parts play a crucial role in ensuring the safety and efficiency of battery packs. In applications such as electric vehicles, where reliability is paramount, nickel parts must meet stringent safety standards to prevent issues such as overheating, short circuits, or electrical failures.

Thermal Management: Nickel parts help in distributing heat within the battery pack, preventing overheating and ensuring that the battery operates within safe temperature ranges.

Electrical Efficiency: The high conductivity of nickel parts ensures that electricity flows efficiently between the cells, minimizing energy loss and improving the overall performance of the battery pack.

Long-Term Durability: The corrosion-resistant properties of nickel ensure that the battery components last longer, reducing the need for maintenance or replacement.

By ensuring that nickel parts are correctly stamped and customized for the specific needs of battery systems, manufacturers can significantly enhance the safety, efficiency, and longevity of their products.

Conclusion

In conclusion, nickel parts stamping is an essential process for creating high-quality, reliable components used in battery assemblies. By carefully selecting the right materials, addressing common challenges in stamping, and adhering to best practices for quality control, manufacturers can ensure that their nickel parts meet the strict standards required for modern battery systems. Arida Machinery specializes in providing custom nickel parts for battery pack assembly, offering tailored solutions that enhance performance, efficiency, and safety.

If you are looking for custom nickel parts to optimize your battery systems, contact us at Arida Machinery today to explore our high-quality solutions.

FAQ

1. What types of nickel parts are used in battery pack assemblies?

The main types of nickel parts used in battery assemblies are nickel sheets, nickel strips, and nickel taps, each with a specific function, such as conducting electricity or connecting cells in series or parallel.

2. How do I choose between nickel sheets and nickel strips for battery applications?

Nickel sheets are used for larger components such as connectors and terminals, while nickel strips are ideal for busbars and current conductors due to their flexibility and ability to handle high currents.

3. What challenges are involved in nickel parts stamping for battery assemblies?

Common challenges include maintaining precision and tolerance control, ensuring the material is free from defects, and customizing parts to meet specific battery system requirements.

4. Why is quality control important in nickel parts stamping for batteries?

Rigorous quality control ensures that nickel parts meet the required specifications for performance, reliability, and safety, preventing defects that could compromise the battery’s efficiency and lifespan.