Have you ever wondered how small metal parts are made efficiently? Cold heading is a critical process in manufacturing that shapes metal without heating it.

In this article, we’ll explore what cold heading is and why it matters. You’ll learn about the cold heading machine and its advantages over traditional methods.

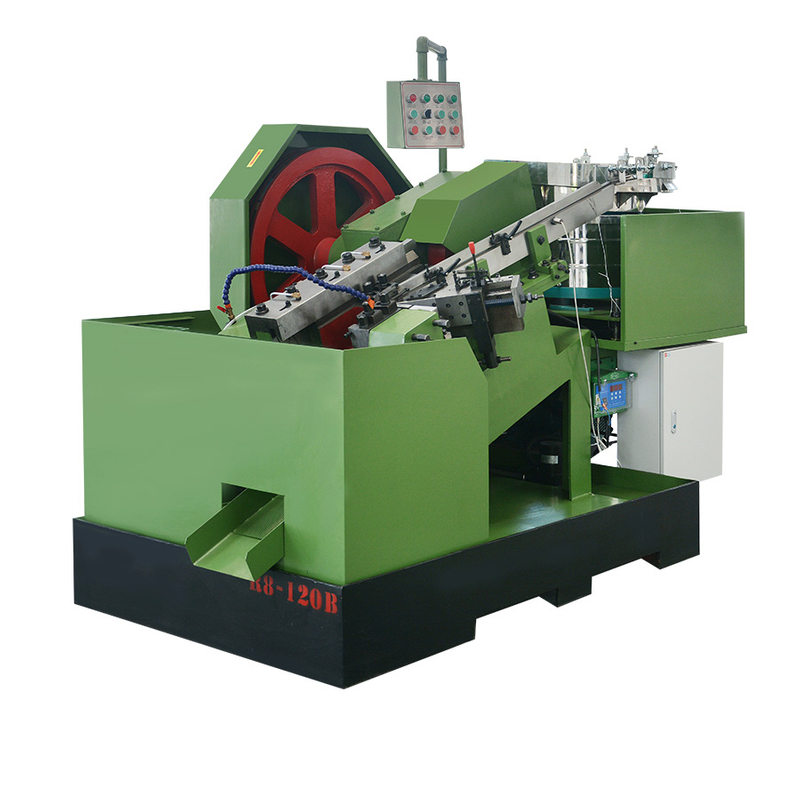

The Cold Heading Machine

What is a Cold Heading Machine?

A cold heading machine is a specialized piece of equipment used in the manufacturing process of cold heading. It shapes metal into various forms without heating it first. This method allows for efficient production of high-quality parts, which is essential in industries like automotive and aerospace.

The machine operates by applying significant force to a metal blank, transforming it into a desired shape through a series of dies. This process is not only efficient but also ensures that the final products maintain precise dimensions and consistent quality.

Key Features of Cold Heading Machines

Cold heading machines come equipped with several impressive features:

● High-Speed Production: These machines can produce between 60 to 800 pieces per minute, depending on the complexity of the part being manufactured. This high throughput significantly enhances productivity.

● Precision and Consistency: One of the standout benefits is their ability to produce parts with exact measurements. This precision is crucial for components that must fit together perfectly in assemblies.

● Automation and Efficiency: Many cold heading machines are designed for unmanned operation. This automation reduces labor costs and minimizes human error, allowing for continuous production runs.

Here’s a quick overview of the key features:

Feature | Description |

Production Speed | 60 to 800 pieces per minute |

Precision | High accuracy in dimensions |

Automation | Capable of unmanned operation |

Types of Cold Heading Machines

Cold heading machines vary in configuration, typically ranging from one to nine stations. Each station can perform different operations, allowing for the production of complex shapes in a single cycle.

Advantages of Multi-Station Machines

Multi-station machines offer several advantages over single-station models:

● Complex Shapes: They can produce intricate designs that would require multiple steps in a single-station machine.

● Increased Efficiency: By performing several operations simultaneously, they reduce the overall production time.

● Flexibility: These machines can be easily adjusted for different products, making them versatile for various manufacturing needs.

In summary, cold heading machines are vital in modern manufacturing. Their ability to produce high-quality, precise parts quickly and efficiently makes them indispensable in many industries. With advancements in technology, these machines continue to evolve, further enhancing their capabilities and applications.

The Cold Heading Process

How Does Cold Heading Work?

Cold heading is a fascinating process that transforms metal into precise shapes without the need for heating. It relies on applying immense pressure to a metal blank, which reshapes it through a series of dies and punches. This method not only saves energy but also enhances the material properties of the finished product.

Step-by-Step Explanation of the Cold Heading Process

1. Material Preparation: The process begins with selecting a suitable metal blank, typically cut to the desired length.

2. Feeding the Blank: The blank is fed into the cold heading machine, where it is positioned for the first operation.

3. Force Application: A punch applies significant force to the blank, pressing it into a die. This action shapes the metal into the desired form.

4. Multiple Operations: The machine may perform several operations in one cycle, allowing for complex shapes to be created efficiently.

5. Finishing Touches: After shaping, the parts may undergo additional processes like trimming or surface finishing to ensure quality.

Here’s a visual representation of the cold heading process:

Step | Description |

Material Prep | Select and cut metal blanks |

Feeding | Position the blank in the machine |

Force Application | Shape the metal using punches and dies |

Multiple Operations | Create complex shapes in one cycle |

Finishing | Trim and finish the product |

Materials Used in Cold Heading

The choice of material plays a significant role in the cold heading process. Common materials include:

● Low Carbon Steel: Known for its ductility and strength, making it ideal for various applications.

● Stainless Steel: Offers corrosion resistance, suitable for demanding environments.

● Copper: Excellent electrical conductivity, often used in electrical components.

● Aluminum Alloys: Lightweight and corrosion-resistant, perfect for automotive and aerospace industries.

Impact of Material Choice on the Final Product

The selected material affects not just the strength and durability of the final product but also its cost-effectiveness and suitability for specific applications. For instance, low carbon steel is often chosen for its balance of cost and performance, while stainless steel is preferred for applications requiring high corrosion resistance.

In conclusion, understanding the cold heading process and the materials involved is crucial for manufacturers aiming to produce high-quality components efficiently. Each step, from material selection to the application of force, plays a vital role in determining the success of the final product.

Applications of Cold Heading

Where is Cold Heading Used?

Cold heading is a critical manufacturing process utilized across various industries. Its ability to produce high-strength, precise components efficiently makes it indispensable in sectors ranging from automotive to aerospace. Let’s explore how different industries leverage cold heading technology to meet their production needs.

Overview of Industries Utilizing Cold Heading

Cold heading finds applications in numerous fields, each benefiting from its unique advantages. Here’s a breakdown of the major sectors:

Industry | Market Share (%) | Key Applications |

Automotive | 34% | Fasteners, bolts, and engine components |

Mechanical Parts Manufacturing | 20% | Gears, shafts, and various mechanical assemblies |

Railway and Aerospace | 15% | Structural components and fasteners |

Electrical and Electronic | 10% | Connectors, terminals, and circuit components |

Military and Shipbuilding | 8% | Specialized fasteners and structural parts |

Petroleum, Chemical, and Construction | 13% | Valves, fittings, and heavy machinery parts |

Detailed Look at Major Sectors

Automotive Industry

The automotive sector is the largest user of cold heading, accounting for approximately 34% of the market share. Cold heading machines produce essential components like bolts, nuts, and fasteners that are critical for vehicle assembly. These parts must meet stringent quality standards, and cold heading ensures high precision and strength.

Mechanical Parts Manufacturing

In mechanical parts manufacturing, cold heading is used to create gears, shafts, and other assemblies. The process allows for the efficient production of high-volume components while maintaining tight tolerances, which is vital for machinery and equipment performance.

Railway and Aerospace Applications

Cold heading is also prevalent in railway and aerospace industries. Components such as structural fasteners and fittings are produced using this method, ensuring they can withstand high stresses and environmental conditions. The reliability of these parts is crucial for safety and performance.

Real-World Examples of Cold Heading Applications

Cold heading technology has been employed in various notable products. Here are a few examples:

● Automotive Fasteners: High-strength bolts used in engine assemblies, which must endure extreme conditions.

● Aerospace Components: Fasteners that secure critical parts in aircraft, ensuring safety during flight.

● Electrical Connectors: Terminals produced through cold heading that provide reliable electrical connections in consumer electronics.

By examining these applications, it becomes clear how essential cold heading is in producing reliable, high-quality components across diverse industries. The ability to create strong, precise parts efficiently makes cold heading a preferred choice for many manufacturers.

Downstream Products of Cold Heading

What Products Are Produced Through Cold Heading?

Cold heading is a versatile manufacturing process that creates a wide range of products essential for various industries. By reshaping metal without heating it, cold heading machines produce high-strength components that are vital in many applications. Let’s delve into the key products generated through this innovative process.

Overview of Key Downstream Products

Cold heading yields several critical components, including:

Product Type | Description | Common Uses |

Cold Heading Wire | Wire specifically designed for cold heading | Used in fasteners and structural components |

Cold Heading Dies | Tools that shape the metal during the process | Essential for ensuring precision in production |

Cold Heading Fasteners | Various fasteners made from cold headed materials | Used in automotive, construction, and machinery |

Cold Heading Bolts | Strong bolts produced through cold heading | Found in machinery, vehicles, and infrastructure |

Cold Heading Wire: Importance and Specifications

Cold heading wire serves as the foundation for many downstream products. It is produced to specific diameters and tensile strengths, ensuring it meets the rigorous demands of different applications. This wire is typically made from materials like low carbon steel or stainless steel, offering excellent ductility and strength. The specifications often include:

● Diameter Range: Commonly from 0.5 mm to 20 mm.

● Tensile Strength: Varies based on application, typically between 300 MPa to 1000 MPa.

● Surface Finish: Can be coated or treated for corrosion resistance.

Cold Heading Dies: Role in the Cold Heading Process

Cold heading dies are crucial tools that shape the wire into various forms. These dies must be precisely engineered to ensure accuracy and consistency in production. They come in different designs depending on the final product required, such as:

● Forming Dies: Used to create specific shapes.

● Trimming Dies: Cut excess material to achieve the desired length.

● Punching Dies: Create holes or indentations in the products.

The quality of the dies directly impacts the efficiency and quality of the cold heading process, making them a vital component in the production line.

Cold Heading Fasteners: Types and Uses

Fasteners produced through cold heading include nuts, bolts, and screws, which are integral to assembly processes in many industries. Here are some common types:

● Hex Bolts: Used in construction and machinery for their strength.

● Socket Head Caps: Ideal for applications requiring a clean aesthetic and high torque.

● Self-tapping Screws: Common in electronics and automotive applications.

These fasteners are designed to provide reliable connections, ensuring the integrity of assembled products.

Cold Heading Bolts: Variants and Applications

Bolts created through cold heading come in various forms, each tailored for specific applications. Notable variants include:

● Carriage Bolts: Used in wood and metal fastening.

● Anchor Bolts: Essential for securing structures to concrete.

● Eye Bolts: Used for lifting and rigging applications.

These bolts are widely used in industries such as automotive, construction, and manufacturing, where strong, durable connections are paramount.

How Do These Products Fit Into Various Industries?

The products generated through cold heading play a significant role across multiple sectors. In the automotive industry, for instance, fasteners and bolts are essential for vehicle assembly, ensuring safety and performance. In construction, cold heading fasteners secure structural components, contributing to the overall stability of buildings and infrastructure.

Discussion on the Importance of These Products in Manufacturing and Assembly Processes

The significance of cold heading products cannot be overstated. They enhance the efficiency of manufacturing processes, reduce production costs, and improve the reliability of assembled products. By providing strong, precise components, cold heading supports the demands of modern manufacturing and assembly, making it an indispensable part of the industrial landscape.

Advantages of Cold Heading

What Are the Benefits of Using Cold Heading?

Cold heading offers numerous advantages that make it a preferred manufacturing process in various industries. By utilizing a cold heading machine, manufacturers can achieve significant benefits that enhance production efficiency and product quality. Here, we explore some of the key advantages of this innovative technique.

Cost-Effectiveness Due to Material Efficiency

One of the standout benefits of cold heading is its cost-effectiveness. This process minimizes waste by using only the necessary amount of material to create parts. Unlike traditional machining methods, which often involve cutting away excess material, cold heading shapes the metal without generating scrap. For example, a comparison of material usage shows that cold heading can reduce waste by up to 30%, leading to substantial savings.

Process Type | Material Waste (%) | Cost Implications |

Cold Heading | 5-10% | Lower material costs |

Machining | 20-40% | Higher material costs |

This efficiency not only lowers costs but also supports sustainable manufacturing practices by reducing the overall material footprint.

Reduction in Production Time and Labor Costs

Cold heading significantly cuts down production time. The process allows for high-speed production of components, often in a matter of seconds. This rapid cycle time means manufacturers can produce large quantities of parts quickly, which is essential in meeting market demands. Additionally, the automation of cold heading machines reduces the need for extensive manual labor, further decreasing labor costs.

For instance, while traditional machining might take minutes per part, cold heading can produce multiple parts in the same timeframe. This efficiency translates to faster turnaround times and increased productivity in the manufacturing process.

Enhanced Product Durability and Reliability

Products manufactured through cold heading exhibit superior durability and reliability. The cold working process strengthens the material, enhancing its mechanical properties. This results in components that can withstand higher stresses and harsher environments, making them ideal for critical applications.

Key benefits include:

● Improved Tensile Strength: Cold heading increases the tensile strength of metals, making them less prone to failure.

● Consistent Quality: The precision of cold heading ensures uniformity in product dimensions, leading to reliable performance.

● Corrosion Resistance: Many cold headed products can be treated for enhanced resistance to corrosion, extending their lifespan.

How Does Cold Heading Compare to Other Manufacturing Processes?

When comparing cold heading to other manufacturing techniques, it’s clear that it holds several advantages. For example, traditional machining often involves cutting, drilling, or milling, which can be time-consuming and generate significant waste. In contrast, cold heading forms parts through deformation, which is generally faster and more efficient.

Comparison with Machining and Other Metal Forming Techniques

To illustrate the differences, here’s a brief comparison of cold heading versus machining and other metal forming processes:

Feature | Cold Heading | Machining | Other Metal Forming |

Material Waste | Low (5-10%) | High (20-40%) | Variable (depends on method) |

Production Speed | Very High | Moderate | Varies |

Labor Intensity | Low (automated) | High (manual intervention) | Moderate |

Product Strength | High | Moderate to High | Varies |

This table highlights how cold heading stands out in terms of efficiency and material usage, making it an attractive option for manufacturers looking to optimize their production processes.

By leveraging the advantages of cold heading, businesses can enhance their manufacturing capabilities, reduce costs, and produce high-quality components that meet industry standards.

Challenges and Considerations in Cold Heading

What Are the Limitations of Cold Heading?

While cold heading is a highly efficient manufacturing process, it does come with certain limitations. Understanding these challenges is crucial for manufacturers looking to optimize their operations. One primary limitation is the type of materials that can be effectively processed. Not all metals respond well to cold heading; for instance, very hard or brittle materials may crack or fail during the forming process.

Moreover, the complexity of the part design can also pose challenges. Intricate shapes or features may require additional machining after cold heading, which can negate some of the efficiency benefits.

Potential Challenges in the Process

Several challenges can arise during cold heading operations. One significant issue is tooling wear. The dies and punches used in cold heading are subject to high stress and friction, leading to wear over time. This can affect the quality of the produced parts and necessitate frequent replacements or maintenance.

Another challenge involves material limitations. Different metals exhibit varying responses to cold working, and selecting the wrong material can lead to product defects. For example, materials that are too ductile may deform improperly, while those that are too hard may not form at all.

Challenge | Description | Impact on Production |

Tooling Wear | High stress leads to rapid wear of dies | Increased downtime for maintenance |

Material Limitations | Not all metals are suitable for cold heading | Potential for defects or failures |

Complex Part Designs | Intricate shapes may require additional processing | Reduces overall efficiency |

Considerations for Material Selection and Machine Setup

When setting up a cold heading operation, material selection is critical. Manufacturers must choose materials that can withstand the forming process without cracking or deforming. Common choices include low carbon steel and certain alloys, which provide a good balance of ductility and strength.

Machine setup is equally important. Proper alignment of the cold heading machine ensures that the dies and punches function correctly, minimizing the risk of defects. Additionally, adjusting the machine parameters, such as speed and pressure, can optimize the forming process for different materials.

How Can Manufacturers Overcome These Challenges?

To tackle the challenges associated with cold heading, manufacturers can adopt best practices that enhance operational efficiency. Regular maintenance of the cold heading machine is essential. By keeping the equipment in good condition, manufacturers can reduce downtime and improve the quality of the parts produced.

Implementing a quality control system is also vital. Regular inspections of the finished products help identify any defects early, allowing for timely adjustments in the process.

Best Practices for Optimizing Cold Heading Operations

Here are some effective strategies for optimizing cold heading:

● Material Testing: Conduct tests on materials before full-scale production to ensure compatibility.

● Tooling Management: Keep a schedule for die maintenance and replacement to prevent unexpected failures.

● Process Monitoring: Utilize sensors to monitor machine performance and detect issues in real-time.

Best Practice | Description | Benefits |

Material Testing | Evaluate materials before use | Reduces risk of defects |

Tooling Management | Regularly maintain and replace tools | Enhances product quality |

Process Monitoring | Use technology to track machine performance | Improves efficiency and reduces downtime |

By addressing these challenges proactively, manufacturers can fully leverage the advantages of cold heading while minimizing potential setbacks. Regular maintenance and a strong focus on quality control create a robust framework for successful cold heading operations.

Future of Cold Heading

What Trends Are Shaping the Future of Cold Heading?

The future of cold heading is influenced by several key trends that are transforming the industry. One of the most significant trends is the push towards more energy-efficient manufacturing processes. As companies strive to reduce their carbon footprints, innovations in cold heading machine technology are emerging. These advancements often include energy-saving features, such as improved motor efficiency and optimized cycle times, which not only lower energy consumption but also enhance overall productivity.

Additionally, the growing demand for high-quality fasteners and components in various industries is driving the evolution of cold heading practices. Sectors like automotive, aerospace, and electronics are increasingly relying on cold headed parts due to their superior strength and precision.

Innovations in Cold Heading Machine Technology

Recent innovations in cold heading machines are revolutionizing how manufacturers operate. Newer models often incorporate smart technology, allowing for real-time monitoring and adjustments during production. This capability helps ensure consistent quality and reduces waste.

Here are some notable technological advancements:

● Energy-Efficient Motors: These motors consume less power while maintaining high performance levels.

● Automation Features: Enhanced automation reduces the need for manual intervention, increasing speed and efficiency.

● Data Analytics Integration: Machines equipped with data analytics can predict maintenance needs, preventing downtime.

Innovation | Description | Benefits |

Energy-Efficient Motors | Lower power consumption | Cost savings and reduced environmental impact |

Automation Features | Increased automation in production | Higher throughput and reduced labor costs |

Data Analytics Integration | Predictive maintenance capabilities | Minimizes unexpected breakdowns |

How Is the Cold Heading Market Expected to Evolve?

Looking ahead, the cold heading market is projected to evolve significantly. Market analysts forecast a compound annual growth rate (CAGR) of 2.6% through 2031. This growth is largely attributed to the rising demand from various sectors, particularly automotive and manufacturing. As these industries expand, the need for reliable and high-quality cold headed components will continue to increase.

Market Growth Projections

The following table illustrates the expected growth trajectory of the cold heading market over the next several years:

Year | Market Size (USD Billion) | CAGR (%) |

2023 | 5.0 | - |

2024 | 5.1 | 2.6 |

2025 | 5.2 | 2.6 |

2031 | 6.2 | 2.6 |

Opportunities Driven by Rising Demand

The automotive sector is one of the primary drivers of growth in the cold heading market. As the demand for lightweight and durable components increases, manufacturers are looking for efficient ways to produce these parts. Cold heading provides an ideal solution, offering strength and precision at lower costs compared to traditional methods.

Moreover, emerging markets in Asia and South America are experiencing rapid industrialization, further fueling the demand for cold headed products. Manufacturers who adapt to these trends and invest in advanced cold heading machines will be well-positioned to capture new opportunities in these growing markets.

By embracing innovation and focusing on sustainability, the cold heading industry is set to thrive in the coming years, providing manufacturers with the tools they need to meet evolving market demands.

Conclusion

Cold heading is a vital manufacturing process. It shapes metal into precise components efficiently.

The technology behind cold heading machines is evolving, focusing on energy efficiency and automation.

This process is crucial for industries like automotive and aerospace, ensuring high-quality parts.

We encourage readers to explore more about cold heading. Inquire about services or products related to this innovative technique.