Introduction

Is cold heading the same as cold forging? This question often confuses many in the manufacturing industry. Both are key metal forming processes, commonly used for high-volume production of small, high-strength parts.In this article, we’ll clarify the differences between cold heading and cold forging. We’ll also highlight the advantages of Arida Machinery's equipment in choosing the right process for your needs.

What Is Cold Heading?

Cold heading is a process that shapes metal bars or wires using pressure inside a die. Unlike hot forging, it doesn’t require heating, which keeps the metal strong. It is perfect for making small, high-strength parts efficiently. The metal is progressively formed through multi-station machines, ensuring each component is precise and uniform.It is widely used in modern manufacturing for small, durable parts. Cold heading increases metal strength through work hardening while keeping its original properties. Since it shapes rather than cuts, it produces minimal waste, making production cost-effective and eco-friendly. High-speed cycles allow manufacturers to make thousands of pieces every hour.

This technique works especially well for bolts, screws, rivets, and nuts. Tight tolerances and smooth finishes are easy to achieve, making cold heading crucial in automotive, electronics, aerospace, and construction industries. It guarantees consistency across large production batches.

Cold Heading Applications

Cold heading is ideal for high-volume production. Manufacturers use it to make thousands of small components fast without sacrificing quality. It handles complex shapes for small parts while keeping them strong and precise.The process is perfect for high-precision components needing consistent dimensions in every batch. For example, automotive and aerospace bolts require strict tolerances. Cold heading produces uniform parts that often need no extra finishing.The fastener industry benefits most. Rivets, screws, nuts, and other small components can be produced quickly, efficiently, and with minimal waste. This reduces cost and improves throughput.

| Application | Key Benefit | Typical Industry |

| Bolts & Screws | Consistent precision | Automotive, Aerospace |

| Rivets & Pins | High-speed production | Electronics, Construction |

| Custom Small Parts | Strong, accurate components | Machinery, Industrial |

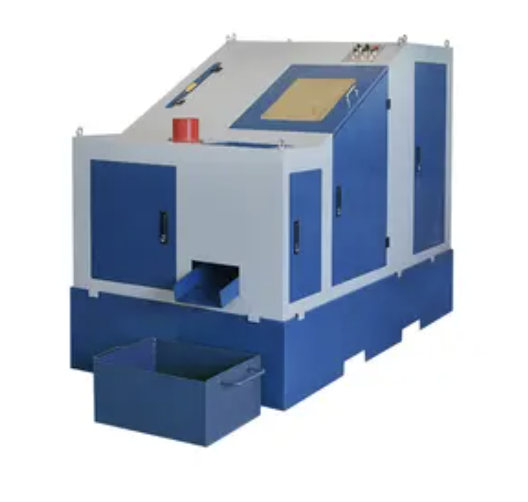

Arida Machinery’s Cold Heading Machines

Arida Machinery offers advanced cold heading machines built for efficiency and precision. Multi-station systems form metal progressively, delivering accurate and repeatable results for every part. They maintain high production speeds without sacrificing quality.Our machines handle various wire sizes, materials, and custom shapes. Automated feeding, lubrication, and quality monitoring ensure smooth operation. High-volume production is possible while keeping tight tolerances and smooth finishes on every piece.Key advantages of Arida Machinery cold heading machines include high efficiency, superior accuracy, and reduced material waste. Manufacturers lower production costs while delivering top-quality fasteners, making these machines ideal for small, high-strength component production.

| Feature | Benefit |

| Multi-station Design | Continuous, high-speed production |

| Tight Tolerance Control | Uniform, precise parts |

| Material Efficiency | Reduces scrap and lowers cost |

Cold Forging Process Overview

Cold forging is a metal forming technique where high pressure shapes a metal blank inside a die. The metal flows plastically under force, taking the exact shape of the mold. This method does not require heating, which preserves the material’s strength and durability.It works well for a variety of metals, including steel, stainless steel, aluminum alloys, and brass. The process enhances mechanical properties while keeping dimensional accuracy high. Manufacturers use it for parts that require tight tolerances, smooth surfaces, and high strength.Cold forging is ideal for complex shapes and medium-to-large components like gears, shafts, and automotive parts. It allows for repeatable production and minimal material waste. This makes it both cost-effective and energy-efficient.

Cold Forging Steps

Prepare the Metal Blank: Ensure it is clean, defect-free, and correctly sized for the die.

Place Metal in Die: The blank is positioned precisely to ensure proper flow and shape formation.

Apply High Pressure: Press or hammer the metal into the die. Plastic flow fills the die cavity completely.

Finishing (Optional): Surface treatment or minor machining ensures the part meets exact specifications.

| Step | Purpose | Notes |

| Prepare Blank | Reduce defects | Clean, pre-cut material |

| Die Placement | Correct alignment | Avoid uneven deformation |

| Apply Pressure | Shape formation | Use high-strength presses |

| Finishing | Improve surface | Optional based on requirement |

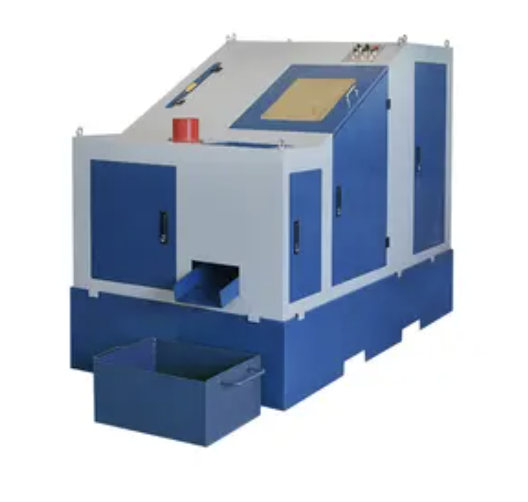

Arida Machinery Cold Forging Equipment

Arida Machinery offers cold forging machines designed for high-pressure performance. They handle complex shapes and strong metals efficiently. Our machines are engineered to manage heavy-duty loads without compromising precision.They support various material types, sizes, and batch volumes. Automation features like material feeding, monitoring, and die lubrication make operations smoother. You get precise, strong, and consistent parts with reduced manual labor.

Key Advantages of Arida Cold Forging Machines:

High load capacity for large or tough components

Excellent dimensional accuracy

Efficient production of complex shapes

Reduced material waste and operating cost

| Feature | Benefit |

| High Load Capacity | Handles tough, large components |

| Automation | Increases efficiency, reduces errors |

| Precision Dies | Ensures tight tolerances consistently |

| Material Flexibility | Works with steel, aluminum, stainless steel |

Cold Forging Process Overview

Cold forging shapes metal at room temperature using high pressure and precision dies. The metal plastically flows, filling the die to form the desired shape. It avoids heating, keeping material strength intact while improving surface finish and durability.This process works on various metals, including steel, aluminum alloys, and stainless steel. Each material responds differently to pressure, so proper setup ensures consistent results. Cold forging suits parts that need high strength, exact dimensions, and smooth surfaces.The process typically involves several steps: cutting a blank, placing it in the die, applying high pressure, and removing the finished part. This sequence can be automated for high-volume production while maintaining accuracy and efficiency.

Cold Forging Applications

Cold forging produces many types of components:

Shafts and axles for automotive or industrial machinery

Gears and pinions requiring precise teeth

Structural parts with complex shapes

| Component Type | Example | Why Cold Forging? |

| Shafts | Drive shafts | High strength, tight tolerances |

| Gears | Transmission gears | Precision teeth, durable surfaces |

| Structural Parts | Aerospace brackets | Complex shapes, strong performance |

Arida Machinery Cold Forging Equipment

Arida Machinery offers advanced cold forging machines for complex, high-strength parts. Their equipment handles large blanks and intricate geometries.Key advantages include high load capacity, automated operations, and precise die control. They help manufacturers improve efficiency, reduce material waste, and ensure repeatable quality.

Features of Arida Cold Forging Machines:

Supports high-pressure operations for tough metals

Maintains tight tolerances and surface quality

Automated workflow for higher throughput

Energy-efficient design for cost savings

| Feature | Benefit |

| High Load Capacity | Handles large and complex parts |

| Precision Dies | Consistent micron-level accuracy |

| Automation | Faster production, reduced errors |

| Energy Efficiency | Lower operational costs |

Is Cold Heading the Same as Cold Forging?

Many people ask if cold heading and cold forging are the same. They both shape metal at room temperature, but they serve different purposes. Cold heading is ideal for small, simple parts, while cold forging handles larger or more complex components.The main difference lies in the size, complexity, and production needs of the parts. Cold heading uses wire or rod stock, forming bolts, screws, and nuts quickly. Cold forging works on larger blanks, producing shafts, gears, and structural parts with high precision.

Here’s a quick comparison table:

| Aspect | Cold Heading | Cold Forging |

| Part Size | Small parts (bolts, nuts) | Small to large parts (gears, shafts) |

| Complexity | Simple shapes | Complex geometries |

| Production Efficiency | Very high | High, suitable for high-strength parts |

| Machines | Multi-station cold heading machines | High-pressure cold forging presses |

| Material | Wire/rod stock | Large metal billets |

Key takeaways:

Cold heading excels at producing small, high-volume, simple parts, perfect for fasteners.

Cold forging suits complex, large, or high-strength parts, widely used in automotive, aerospace, and industrial machinery.

Arida Machinery offers both cold heading and cold forging machines to optimize production efficiency and part quality.

When to Use Cold Heading vs Cold Forging

Selecting the right process between cold heading and cold forging is crucial for manufacturing efficiency. While both methods shape metal at room temperature, they serve different purposes. Cold heading is typically used for small, high-volume parts, whereas cold forging handles larger, more complex components that demand higher strength and precision. Understanding the differences ensures the right choice for your production needs.

Cold Heading Applications

Cold heading is best suited for small, standardized components that require rapid production. It allows manufacturers to produce hundreds of parts per minute, making it ideal for high-volume operations. Fasteners like bolts, screws, nuts, and rivets are commonly produced using this method.The process maintains tight tolerances and precise dimensions without additional machining. Cold heading uses dies and punches to reshape metal wire or rod, minimizing material waste. This makes it a cost-effective option for mass production.In addition, cold heading ensures consistent part quality across large production runs. Its ability to combine speed, precision, and low waste has made it a preferred choice for the fastener industry.

| Feature | Advantage |

| Part Size | Small components (bolts, screws, rivets) |

| Production Volume | High-volume, hundreds per minute |

| Precision | Tight tolerances for standardized parts |

| Cost Efficiency | Minimal material waste |

Cold Forging Applications

Cold forging is ideal for medium to large components that require higher strength and complex geometries. It uses high-pressure dies to reshape metal, making it suitable for shafts, gears, structural parts, and other intricate mechanical components.This process enhances material strength through cold working and ensures precise dimensions. It is widely applied in automotive, aerospace, and heavy machinery industries, where durability and performance are critical.Cold forging also allows for micron-level accuracy, reducing the need for secondary machining operations. While production speed may be slightly lower than cold heading, it provides superior mechanical properties and reliability for demanding applications.

| Feature | Advantage |

| Part Size | Medium to large components (shafts, gears) |

| Complexity | Handles intricate and complex shapes |

| Strength | High durability and mechanical performance |

| Precision | Micron-level tolerances for critical applications |

Choosing Between Cold Heading and Cold Forging

The choice depends largely on part size, production volume, and functional requirements. Cold heading is the go-to for small, high-volume fasteners where cost and speed are priorities. Cold forging is better for larger, complex, or high-strength components where precision and mechanical performance matter most.

| Process | Best Use | Strengths | Limitations |

| Cold Heading | Small fasteners, high-volume | Fast, precise, low waste | Limited to simple shapes and small parts |

| Cold Forging | Shafts, gears, structural components | Strong, precise, durable | Higher tooling cost, slower production |

Advantages of Choosing Arida Machinery for Cold Heading and Cold Forging Machines

Arida Machinery stands out as a global leader in cold heading and cold forging equipment. Our machines combine advanced technology, precision, and efficiency. They help manufacturers produce high-quality parts faster, reducing waste and operational costs while maintaining tight tolerances.

Technology Leadership

Our machines feature cutting-edge designs and global-standard technology. They provide consistent part quality and high-speed production. Engineers have optimized each component to ensure maximum reliability, accuracy, and performance during extended runs.We integrate advanced control systems for precise die and punch movements. This allows operators to maintain exact tolerances, even for small, intricate parts. They can also switch between part types quickly, improving production flexibility.Arida Machinery invests continuously in research and development. This ensures our cold forming solutions remain at the forefront of global manufacturing technology, providing clients with a competitive edge.

Custom Solutions

We understand that every production line has unique requirements. Arida Machinery offers fully customizable cold heading and cold forging machines to match specific part sizes, volumes, and materials.From single-station machines to multi-station automated systems, they can adapt to different production scales. Our engineers collaborate with clients to optimize layouts, tooling, and automation, ensuring maximum efficiency.

Custom configurations also help clients reduce material waste, improve cycle times, and achieve precise tolerances for high-volume or complex parts.

Reliability and Durability

Arida Machinery designs its equipment for long-term reliability under heavy production loads. Machines can operate continuously in demanding industrial environments without compromising quality.The robust construction and high-strength components minimize downtime and maintenance. Users benefit from predictable performance, ensuring consistent output even during intensive production schedules.

| Feature | Benefit |

| Construction | High-strength materials resist wear and deformation |

| Operation | Long-term stability under heavy loads |

| Maintenance | Reduced downtime, predictable performance |

Energy Efficiency and Eco-Friendliness

Our machines are engineered for energy efficiency. They consume less power compared to conventional cold forming equipment, reducing operational costs and environmental impact.By minimizing energy usage, we help clients lower their carbon footprint while maintaining production quality. Efficient hydraulic and servo systems contribute to precise, repeatable operations with lower energy waste.

Technical Support

Arida Machinery offers full technical support and after-sales service. Our team provides installation guidance, maintenance training, and troubleshooting to ensure machines run smoothly.Clients can access expert assistance whenever needed. This support extends the equipment lifespan, reduces unexpected downtime, and ensures production goals are consistently met.

| Support Aspect | Description |

| Installation | Professional setup for optimal performance |

| Training | Operator guidance for safe, efficient use |

| Maintenance | Scheduled and on-demand service for longevity |

| Troubleshooting | Quick resolution of any production issues |

Conclusion

Cold heading and cold forging differ in size, complexity, and applications. Cold heading excels in small, high-volume parts production, while cold forging handles larger, complex components. Arida Machinery provides advanced cold heading and forging machines that ensure precision, efficiency, and reliability. Their equipment supports high-speed production, reduces material waste, and maintains consistent quality. Choosing Arida Machinery helps manufacturers achieve better performance and lower costs.

FAQ

Q: What is cold heading?

A: Cold heading is a metal forming process that shapes wire or rods into small parts without heating.

Q: How does cold heading differ from cold forging?

A: Cold heading focuses on small, high-volume parts, while cold forging handles larger, complex components.

Q: Why use cold heading for fasteners?

A: Cold heading produces precise bolts, screws, and rivets efficiently, reducing material waste and cost.

Q: What metals work for cold heading machines?

A: Steel, aluminum, and stainless steel are commonly used in cold heading processes for durable parts.

Q: Are Arida Machinery cold heading machines energy-efficient?

A: Yes, they offer high-speed production with minimal energy consumption and reduced material waste.

Q: Can cold forging replace cold heading?

A: Cold forging is ideal for larger or complex parts, but small fasteners benefit most from cold heading.