Nickel stamping refers to the process of shaping and forming nickel-based alloys into specific parts using specialized dies and presses. Nickel alloys, such as Inconel, Monel, and Hastelloy, are particularly valuable in industries where parts must withstand extreme environmental conditions such as high temperatures, pressure, and corrosion.

This article delves into the industries that utilize nickel stamping, detailing how nickel alloys are leveraged for their durability, versatility, and superior properties in various applications.

1. Aerospace Industry

Applications of Nickel Stamping in Aerospace

The aerospace industry demands materials that are not only strong but also resistant to corrosion, oxidation, and extreme temperatures. Nickel alloys are frequently used for stamping aerospace components that perform under these harsh conditions.

Some of the typical parts manufactured using nickel stamping include:

Fasteners: Nickel-stamped fasteners such as bolts, screws, and rivets are crucial in maintaining the integrity of aircraft structures.

Seals: Nickel alloys are used for high-performance seals that prevent leakage and maintain pressure in different parts of aircraft.

Turbine Components: Nickel alloys like Inconel are used in turbine blades and components that face extremely high temperatures.

Why Nickel Alloys Are Ideal for Aerospace

Nickel alloys are known for their outstanding resistance to oxidation and corrosion at high temperatures, which is vital for parts exposed to extreme conditions such as turbine engines or aerospace structural elements. The strength and fatigue resistance of nickel alloys also make them a durable choice for components that need to withstand high mechanical stress and pressure.

2. Energy and Power Generation

Applications of Nickel Stamping in Energy and Power Generation

Nickel-stamped products are also widely used in the energy sector, where components often face high-pressure steam, extreme heat, and corrosive environments.

Common nickel stamping applications in the energy sector include:

Turbine Components: In power generation, turbines made from nickel alloys can handle the extreme temperatures generated during the production of electricity, especially in nuclear, geothermal, and fossil fuel plants.

Pressure Vessels: Nickel alloys are essential for stamping parts used in pressure vessels due to their ability to withstand high pressures and resist corrosion.

Heat Exchangers: Used in both traditional power plants and renewable energy systems, heat exchangers made from nickel alloys ensure efficient heat transfer while resisting damage from thermal cycling and corrosion.

Why Nickel Alloys Are Essential for Power Generation

Nickel alloys’ ability to resist high-temperature oxidation and stress-corrosion cracking in high-pressure environments makes them indispensable for energy and power generation applications. These materials ensure that the components remain reliable and safe for long-term operations, even in extreme environments like those found in nuclear reactors or geothermal energy systems.

3. Chemical and Petrochemical Industry

Applications of Nickel Stamping in Chemical and Petrochemical Industries

The chemical and petrochemical industries often involve processes where components are exposed to aggressive chemicals, corrosive substances, and extreme temperatures. Nickel alloys are specifically engineered for environments where corrosion resistance is paramount.

Some of the parts made using nickel stamping in these industries include:

Valves and Gaskets: Nickel-stamped valves are used to control the flow of chemicals and fluids within a system, ensuring that they operate effectively without leaking.

Heat Exchangers: Nickel alloys are used to create heat exchangers that prevent corrosion from sulfuric acid, hydrochloric acid, and other aggressive chemicals.

Pumps and Compressors: For handling corrosive liquids or gases, nickel alloys in stamping are used to manufacture parts that ensure the pumps and compressors function reliably over time.

Why Nickel Alloys Are Critical for Chemical Processing

Nickel alloys are known for their exceptional resistance to corrosion and acidity. They are used in environments where common metals would degrade quickly. Nickel-based alloys can withstand the effects of acidic chemicals, high-pressure environments, and extreme temperatures, ensuring that critical components remain intact and functional.

4. Marine Industry

Applications of Nickel Stamping in the Marine Industry

Nickel alloys are widely used in the marine industry for manufacturing parts that must endure the corrosive effects of seawater. Whether it is for commercial shipping, naval vessels, or offshore oil rigs, nickel-stamped components play a crucial role in maintaining the structural integrity of marine equipment.

Typical applications include:

Marine Fasteners: Nickel alloys are ideal for fasteners used in shipbuilding because they prevent rust and degradation when exposed to saltwater.

Propeller Shafts: Nickel alloys ensure that propeller shafts can resist corrosion and perform effectively in harsh marine environments.

Desalination Equipment: Many desalination plants rely on nickel-based alloys to make parts such as pumps and heat exchangers, as they resist the corrosion caused by saltwater.

Why Nickel Alloys Are Used in Marine Environments

Nickel alloys are incredibly resistant to saltwater corrosion, which is a major factor in the marine environment. Whether in shipbuilding or oil drilling, nickel alloys are used to extend the lifespan of marine equipment, improving reliability and reducing maintenance costs.

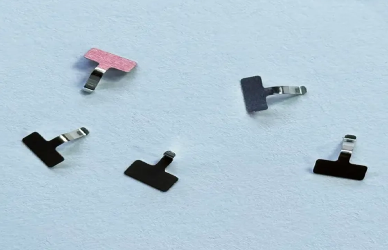

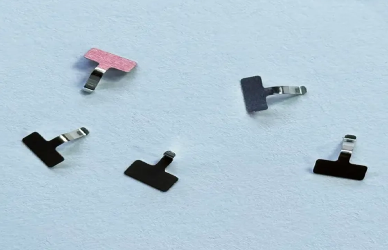

5. Electronics and Electrical Industry

Applications of Nickel Stamping in Electronics and Electrical Industries

Nickel stamping is also used in the electronics and electrical industries for producing precision connectors, electrical contacts, and sensor components that require excellent conductivity and resistance to environmental stress.

Common parts made from nickel alloys include:

Electrical Connectors: Nickel alloys provide the necessary corrosion resistance and conductivity for connectors used in sensitive electronic applications.

Sensor Components: Nickel-based alloys are used to manufacture precision sensors that perform under challenging conditions such as high temperatures and exposure to chemicals.

Why Nickel Alloys Are Ideal for Electronics

Nickel alloys are not only electrically conductive, but they also possess high corrosion resistance, making them perfect for components that need to function reliably in both high-temperature and corrosive environments. Their durability ensures long-term performance, even in sensitive electronics.

6. Automotive Industry

Applications of Nickel Stamping in the Automotive Industry

The automotive industry utilizes nickel-stamped components to manufacture parts that need to withstand high temperatures, pressure, and vibration. Some of the most common applications include:

Exhaust System Components: Nickel alloys are used to stamp exhaust system parts such as catalytic converters, exhaust manifolds, and mufflers.

Fuel System Parts: Fuel injectors, fuel filters, and other components are made from nickel alloys to ensure they perform under harsh conditions.

Why Nickel Alloys Are Crucial in Automotive Manufacturing

Nickel alloys offer excellent heat resistance and corrosion resistance—qualities that are essential for components exposed to extreme conditions like exhaust systems or fuel systems in vehicles. Additionally, they help maintain system durability and efficiency, even in high-performance vehicles.

7. Medical and Pharmaceutical Industry

Applications of Nickel Stamping in Medical and Pharmaceutical Industries

The medical industry uses nickel-stamped products for components that need to meet stringent biocompatibility and strength standards. Nickel alloys are commonly used in:

Medical Devices: Nickel alloys are used in devices such as pacemakers, surgical instruments, and diagnostic tools.

Implants: Components like joint replacements and dental implants made from nickel-based alloys provide biocompatibility and strength.

Why Nickel Alloys Are Used in Medical Applications

Nickel alloys are chosen for their biocompatibility, meaning they do not cause adverse reactions when implanted in the human body. Their strength, resilience, and resistance to corrosion make them perfect for medical devices that must perform in highly demanding conditions, such as inside the human body.

8. Industrial Manufacturing

Applications of Nickel Stamping in Industrial Manufacturing

Nickel alloys are essential in industrial manufacturing, where components experience high mechanical stress and abrasion. Common nickel-stamped parts include:

Machine Components: Nickel alloys are used in gear shafts, bearings, and other critical machine parts that need to endure constant wear and tear.

Manufacturing Tools: Stamped nickel alloys are used for high-performance tools that cut, form, and shape other materials in industrial settings.

Why Nickel Alloys Are Essential in Manufacturing

Nickel alloys are valued for their durability and resistance to wear in heavy-duty manufacturing applications. Their strength and abrasion resistance ensure that industrial machines and tools last longer and perform effectively even under harsh working conditions.

FAQ (Frequently Asked Questions)

1.What industries use nickel stamping products?

Nickel stamping products are used in industries such as aerospace, energy and power generation, chemical and petrochemical, marine, electronics, automotive, medical, and industrial manufacturing.

2.What are the advantages of using nickel alloys for stamping?

Nickel alloys provide corrosion resistance, strength at high temperatures, and durability, making them suitable for extreme environments.

3.How does nickel stamping differ from other stamping processes?

Nickel stamping requires specialized tooling and processes due to the hardness and springback properties of nickel alloys, unlike more commonly used materials like steel or aluminum.

4.Can nickel alloys be used for high-precision parts?

Yes, nickel alloys are used for high-precision stamping in industries like electronics and medical devices.

Conclusion

Nickel stamping products play an essential and pivotal role across a wide range of industries, from aerospace to industrial manufacturing. The unique and superior properties of nickel alloys, including high resistance to corrosion, exceptional strength at elevated temperatures, and unmatched durability in harsh environments, make them the material of choice for producing components that are required to perform under extreme conditions.

These materials ensure reliability, safety, and long-term performance across critical sectors, where the failure of parts could result in serious operational disruptions or safety hazards. Whether it’s in aerospace, energy generation, marine applications, or medical devices, nickel alloys continue to provide solutions for industries seeking parts that stand the test of time and adverse environments. As technology advances and industries evolve, the demand for nickel stamping products will continue to rise, cementing their place as a crucial component in the manufacturing of high-performance, durable, and reliable products.