As the demand for electric vehicles (EVs) and energy storage systems grows, the need for high-quality, reliable, and efficient components becomes ever more critical. One of the most essential materials in the manufacture of these systems is nickel, particularly in the form of custom nickel parts stamping. Nickel sheet and custom stamped nickel parts are indispensable for assembling battery packs that power everything from electric vehicles to power tools and motorcycles. Arida Machinery, a leader in the production of precision nickel parts, plays a vital role in supplying the industry with the high-quality components needed to meet the demands of modern energy storage systems.

In the world of battery technology, nickel is favored for its superior conductivity, resistance to corrosion, and strength, making it ideal for use in battery pack assembly. This article explores the key aspects of custom nickel parts stamping, the process behind it, the benefits it offers for battery applications, and how Arida Machinery ensures the precision and durability of every part we produce.

What is Nickel Parts Stamping?

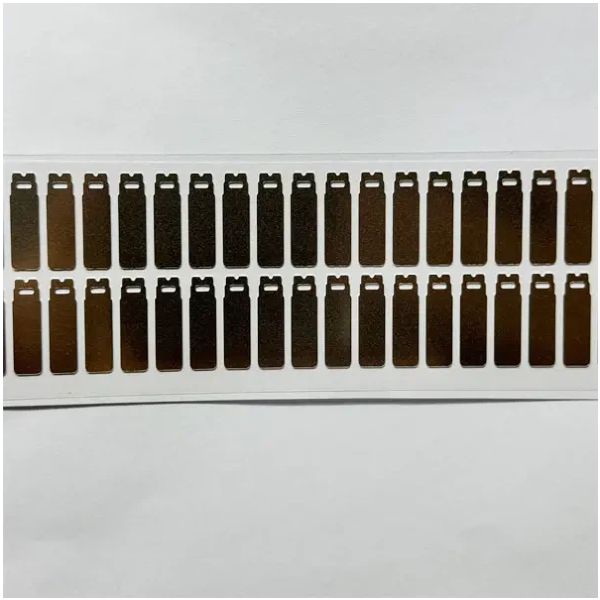

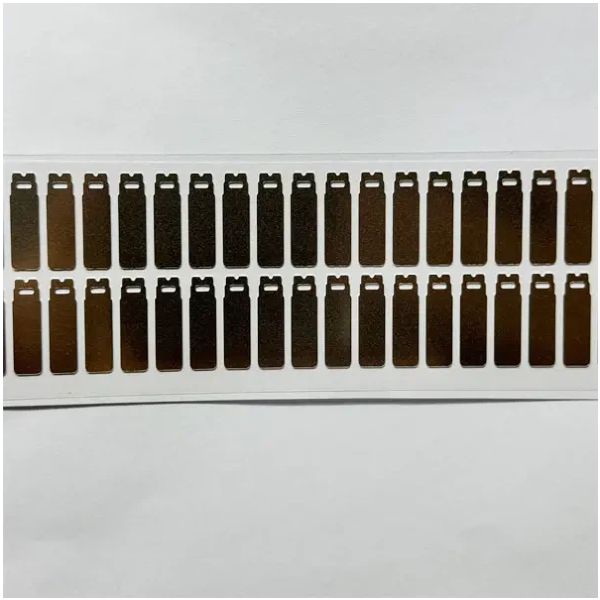

Nickel parts stamping is a specialized process used in manufacturing high-precision components from nickel sheet materials. The process involves using a die to cut and shape nickel sheets into specific forms, ensuring that the final parts meet strict specifications in terms of size, shape, and performance.

In the context of battery accessories, custom nickel parts stamping is an essential process for producing components that are used in battery packs. These components serve various critical functions, such as connecting battery cells, managing electrical current, providing heat dissipation, and ensuring the safety and longevity of the battery pack. By using nickel sheet, manufacturers can produce components that are both electrically conductive and durable, essential for the high-stress, high-voltage environments of modern batteries.

At Arida Machinery, we utilize state-of-the-art technology and high-precision stamping equipment to produce custom stamped nickel parts that meet the exact needs of our clients, particularly those in the electric vehicle and energy storage industries. Our nickel parts are designed to meet the most demanding specifications, ensuring that every product performs optimally in its intended application.

Key Steps in Custom Nickel Parts Stamping

Material Selection and Preparation

The first step in the custom nickel parts stamping process is selecting the right material. The nickel sheet used for battery applications must have the right properties to ensure that the final product will perform as needed. The thickness of the nickel sheet is one of the key considerations, as different parts may require varying thicknesses depending on their application in the battery system.

For battery pack assemblies, it is crucial to select nickel sheets that offer high electrical conductivity and resistance to corrosion. The material must also be strong enough to withstand the mechanical stresses and temperature variations that are common in battery systems. At Arida Machinery, we source only the highest-quality nickel sheets to ensure the durability and performance of our custom-stamped parts.

Stamping Process Overview

Once the material is selected, the next step is the stamping process. The nickel sheet is fed into a press machine, which uses a die to stamp the sheet into the desired shape. The die design is a critical component of this process, as it determines the precision and quality of the final part. At Arida Machinery, we use advanced computer-aided design (CAD) software to create dies that ensure every part meets the strict tolerances required for battery applications.

The stamping process itself involves applying high pressure to the nickel sheet to form the part. Depending on the thickness of the material and the complexity of the part, multiple stamping stages may be required to achieve the final shape. For instance, some parts may require multiple cuts or shaping processes to ensure that all dimensions and functional features are accurate.

At Arida Machinery, we have the capability to handle a wide range of nickel sheet thicknesses and can produce parts as thin as 0.06mm. This flexibility ensures that we can meet the varied needs of our customers, from producing ultra-thin parts for precise battery connectors to more robust components for energy storage systems.

Post-Processing and Quality Control

Once the custom nickel parts are stamped, they undergo post-processing to refine their surface and improve their performance. This may include deburring to remove sharp edges, surface finishing to smooth out any imperfections, or additional treatments like coating or plating to enhance durability.

Quality control is an essential aspect of the post-processing phase. At Arida Machinery, we implement a comprehensive quality control system to ensure that every custom stamped nickel part meets the highest standards. Our inspections include dimensional checks, visual inspections, and functional testing to ensure that each part is free from defects and ready for integration into the final product. Only parts that pass these stringent tests are shipped to our customers, ensuring reliability and performance in every batch.

Applications of Custom Nickel Parts in Batteries

Custom nickel parts are essential components in battery packs used in a wide range of applications. These include electric vehicles (EVs), motorcycles, power tools, and energy storage systems. Nickel’s exceptional electrical conductivity, resistance to corrosion, and strength make it the ideal material for critical battery components.

Here are some key applications of nickel parts in batteries:

Battery Management System (BMS) Connectors: Custom nickel parts are used to create connectors that manage the flow of electricity between cells, ensuring that the battery operates efficiently and safely.

Battery Pack Busbars: Nickel parts are used to connect individual cells within a battery pack. These busbars distribute electrical current to each cell, ensuring that the battery performs optimally. Nickel’s high conductivity makes it an ideal material for this application.

Heat Dissipation Components: Because nickel has high thermal conductivity, it is used in parts designed to dissipate heat from battery cells. This helps maintain the battery’s operating temperature within safe limits, preventing overheating and ensuring the longevity of the system.

For electric vehicles (EVs), motorcycles, and power tools, nickel sheet parts provide the necessary strength and durability to withstand the mechanical stresses these devices encounter during operation. Without reliable, high-performance parts, the battery systems in these applications would be far less efficient and more prone to failure.

Table: Comparison of Nickel Parts Used in Different Battery Applications

Part Type | Application | Key Properties |

Nickel Sheets | Used for connectors, terminals, and busbars in BMS | High conductivity, thin but durable. |

Nickel Strips | Used for busbars and current conductors. | Flexible, excellent conductivity. |

Nickel Taps | Used to connect battery cells in series/parallel | Precision cut, strong and reliable. |

Nickel Heat Dissipation | Used to dissipate heat in battery systems | Excellent thermal conductivity, lightweight. |

Benefits of Custom Nickel Parts for Battery Applications

Durability and Conductivity

One of the most significant advantages of using custom nickel parts in battery applications is their exceptional durability and conductivity. Nickel is a highly conductive material, allowing electricity to flow efficiently through the components of the battery pack. This is essential for the proper functioning of the battery, particularly in high-demand environments like electric vehicles and power tools.

In addition to electrical conductivity, nickel is also known for its resistance to corrosion, which makes it ideal for use in environments that may be exposed to moisture, temperature extremes, and chemical exposure. This ensures that custom stamped nickel parts will not degrade over time, providing long-lasting performance.

Resistance to Corrosion

Battery systems are often exposed to harsh conditions that can accelerate the process of corrosion in many metals. Nickel sheets offer excellent corrosion resistance, which helps extend the lifespan of battery components and reduces the likelihood of failure. This resistance is especially important in applications like electric vehicles and energy storage systems, where the performance and reliability of the battery pack are critical.

Precision and Customization

With custom nickel parts stamping, manufacturers can create components that are specifically tailored to the needs of the application. Arida Machinery’s precision stamping process allows us to produce parts with tight tolerances, ensuring that every component fits perfectly within the battery pack assembly. Whether it’s a high-energy-density battery or a compact system for a power tool, our stamping process can be customized to meet even the most demanding specifications.

Conclusion

In conclusion, custom nickel parts stamping is an indispensable process in the production of high-performance components for battery packs. By selecting high-quality nickel sheet materials, Arida Machinery ensures that each part we produce offers the durability, conductivity, and precision required for modern energy storage systems. Our commitment to excellence in manufacturing and quality control guarantees that every custom stamped nickel part meets the highest industry standards, contributing to the overall efficiency, safety, and longevity of the battery pack.

If you are seeking reliable, high-performance nickel parts for your battery systems, contact us at Arida Machinery to learn more about our tailored solutions.

FAQ

1. What types of nickel parts are commonly used in battery applications?

Custom stamped nickel parts such as connectors, busbars, and heat dissipation components are commonly used in battery packs for electric vehicles and energy storage.

2. Why is nickel the preferred material for battery pack components?

Nickel offers excellent conductivity, durability, and corrosion resistance, making it ideal for parts that must withstand high temperatures and electrical loads.

3. How does the stamping process affect the quality of nickel parts?

The stamping process ensures precise shaping of nickel parts, meeting tight tolerances and specifications necessary for efficient battery pack operation.

4. Can nickel parts be customized for specific battery pack designs?

Yes, custom nickel parts stamping allows for the creation of parts tailored to the specific needs of different battery applications, from electric vehicles to power tools.